|

| BenJ |

|

||

|

{USERNAME} wrote: Any more progress Ben? LOL, you tell me. Just to be clear, SWC is very kindly doing the welding of the AU door pieces for me. This is a trial of an idea, and will either prove the theory or show if it is harder than first thought. Cheers BenJ

_________________ {DESCRIPTION} - Current Ride |

||

| Top | |

||

| XR-Lane |

|

|||

|

Plenty of confidence with SWC with seeing his work on the bonnet

|

|||

| Top | |

|||

| huggiebear |

|

|||

|

agreed. almost worth moving to NSW and becoming friends with him

or i can always just send him an XA or XB base model bonnet to graft to my lane bonnet.. i dont want the vents.. just the humps |

|||

| Top | |

|||

| ToranaGuy |

|

|||

|

The idea on the door handles is good, and I can't wait to see one finished & see what it's like in the flesh.

Keep up the good work BenJ! Cheers ToranaGuy

_________________ I am the ToranaGuy!|74 Lh Torana Turbo|78 Hz PanelVan|86 Mighty Boy Ute|93 EB2 Ghia,GT Mockup,5spd,LPGI,Full Leather|2 x EB Xr8 5spd's|{DESCRIPTION}|{DESCRIPTION}|{DESCRIPTION}| |

|||

| Top | |

|||

| Froudey |

|

||

|

{USERNAME} wrote: {USERNAME} wrote: Any more progress Ben? LOL, you tell me. Just to be clear, SWC is very kindly doing the welding of the AU door pieces for me. This is a trial of an idea, and will either prove the theory or show if it is harder than first thought. Cheers BenJ I am going to keep an eye on that... I want to do this for the 720,

_________________ R.I.P Tobias my son. |

||

| Top | |

||

| SWC |

|

||

|

{USERNAME} wrote: agreed. almost worth moving to NSW and becoming friends with him or i can always just send him an XA or XB base model bonnet to graft to my lane bonnet.. i dont want the vents.. just the humps I have Bonnet or can aquire one in Sydney to suit Fairmont/Lane but you will need to aquire the XB bonnet centre. XA no good as they don't have any hump at all. Another option is to use TC 6cyl Cortina bonnet. Happy to qive you a quote on the work as long as you are happy to pay the freight. |

||

| Top | |

||

| huggiebear |

|

|||

|

i have actually spent the last hour going over what could look good on the NC bonnet. as its soo long and flat nothing will suit it really..

i assume your talking about a TC cortina? they have the box type hump if it is? i might muck around with a few ideas out of interest if the 2 bonnets were suplied, how much would a bonnet graft like bens cost? |

|||

| Top | |

|||

| SWC |

|

||

|

{USERNAME} wrote: i have actually spent the last hour going over what could look good on the NC bonnet. as its soo long and flat nothing will suit it really.. i assume your talking about a TC cortina? they have the box type hump if it is? i might muck around with a few ideas out of interest if the 2 bonnets were suplied, how much would a bonnet graft like bens cost? Alot depends on what you want grafted and condition of Bonnet/ Graft and how much work is involve in clean up and jst how far do you want the bonnet finished. |

||

| Top | |

||

| bradley4567 |

|

||

|

{USERNAME} wrote: agreed. almost worth moving to NSW and becoming friends with him or i can always just send him an XA or XB base model bonnet to graft to my lane bonnet.. i dont want the vents.. just the humps i have an xc bonnet with humps and no vents if you wanna swap me for one with vents, lols

_________________ ef falcon daily driver |

||

| Top | |

||

| huggiebear |

|

|||

|

lol there is one up here with no vents for 25 bucks.. a bit of rust on the frame work, but i wouldnt use it anyways

|

|||

| Top | |

|||

| BenJ |

|

||

|

{USERNAME} wrote: Hey Benj Were you down driving the car down near West Point blacktown round 3-4pm today? I swear i saw ya car, looks and sits well. Actually, yes. I was dropping off the better half. TAXI duties are a large part of the Wagons duties LOL Cheers BenJ

_________________ {DESCRIPTION} - Current Ride |

||

| Top | |

||

| BenJ |

|

||

|

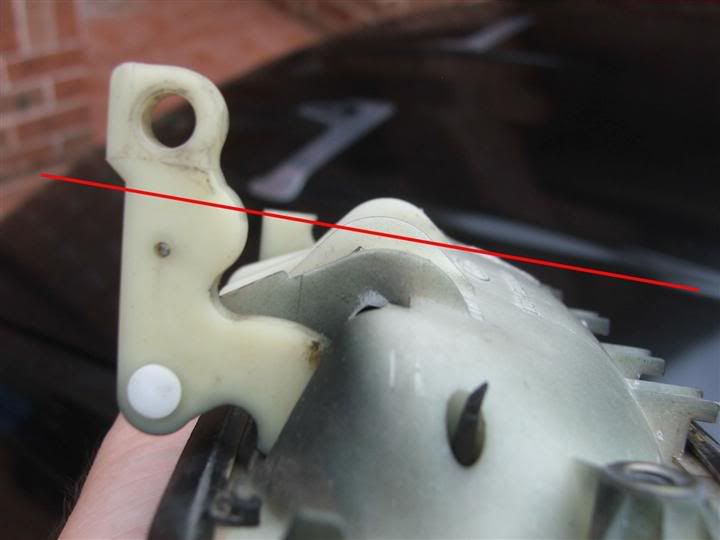

Last week I went down to visit SWC and check out the progress on the AU door handles.

SWC had found an isse with the door, where it appears there was a depression in the skin on the door I gave him to work with, and then when combined with the heat from welding had sucked in the area around the handle. We sussed it out and then with some carefully applied force with a small crowbar, convinced the depression to feel a bit better about it self and come out a bit and join the rest of the door. Some fibreglass bog filler has been applied to the area around the handle and it needs some bog now to finalise the levels. This is how it looks at the moment with the handle bolted in.    Looking very promising at this early stage. Then looking down through the top of the window opening I noticed how far the door handle was protruding into the door cavity, and when I compared to the window runners I could see we were going to have some real issues. I took the door home to apply some BenJ creative thinking and to engineer a solution. This photo shows the glass in place with the AU door handle shell minus the handle mechanism.  As you can see the glass is going to hit the back of the shell. Hmmmm. This photo shows the assembled AU handle and look how far the lever protrodes past the back of the shell. The red line in this photo represents where the glass would be when wound down.  This creates a bit of an issue I think. I analysed the physical movement required for the door latch to release when the handle is lifted. The actual lateral travel was approx 4-5mm before the release catch allowed the latch to open. The arc created by the factory position of the actuator rod from the handle to the latch was more like 15-20mm and there was a lot of freeplay prior to the release catch becoming engaged by the actuator rod. So I grabbed my dremel and drill and set to hacking . . . . . urrr, ahhhh applying carefully measured and calculated cuts to the AU handle. What I ended up with was this. Before  After  And the other side and the raised ridges on the back also got the treatment. Before  After  The finished modified handle and actuator rod.  I also shortened the AU actuator rod. To test the function I used a marine cable clamp to connect the AU and EB actuator rods, and by setting the release latch to partially open, there is sufficient travel to allow the door catch to open. The actuator rods will be welded together before final assembly. The drivers door handle will get the same mods, but luckily as the rear door handles are under the quartervent windows, clearance is not an issue. **************************************************************** Other news is that the Wagon passed it's yearly Pink Slip inspection and registration has been paid, so that is one headache out of the way. I have also received a new Power Steering Pressure switch. I will install that along with a new Pump when I purchase it soon. I have also started prep work on the BA Bumper Bar.  Hope you are all well. Cheers BenJ

_________________ {DESCRIPTION} - Current Ride |

||

| Top | |

||

| fairlane6970 |

|

|||

|

lookin' good there BenJ

_________________

|

|||

| Top | |

|||

| huggiebear |

|

|||

|

i was about to suggest something about the handle but then i scrolled down and seen you beat me to it lol.

looking damn good ben |

|||

| Top | |

|||

| FordFairmont |

|

||

Posts: 6113 Joined: 8th May 2007 |

looks like alot of trouble for not very much gain..... EF/EL handle would be an improvement and alot easier

with all the welding and bogging involded fitting the AU handle, i would be inclined to setup shaved door handles instead, now that would look smoooth |

||

| Top | |

||

| Who is online |

|---|

Users browsing this forum: No registered users and 32 guests |