|

| TimmyA |

|

|||

|

Nope key on and just wound it over with a breaker bar expecting 2 different values... One for when it was seeing the bar and one when the bar was gone... What should I have been seeing?

I tested at the engine harness plug the first time and got nothing so I moved down to the actual plug for the sensor the second time and got pretty much the same nothing... And then started it and it works fine... So was left puzzled to what actually comes out of the sensor and no I don't own an oscilloscope... Cheers, Tim

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| misk_one |

|

|||

|

I'd say the engine needs to be actually running.

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| TimmyA |

|

|||

|

How do you then tell the difference between a high and low pulse? If all that is coming out a big blur of highs and lows?

I still don't understand how it works so that doesn't help me test it for you... Is it not a binary output? A square wave? sine wave? sawtooth wave? If I knew what came out of it then I'd have some idea how I should be testing it... times like this when I wish I did own an oscilloscope... Cheers, Tim

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| misk_one |

|

|||

|

I'd say the engine needs to be actually running.

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| misk_one |

|

|||

|

Most variable reluctance sensors are a sine wave.

Really need to figure out exactly what the sensor is looking at. Ill try get to my brothers factory so I can pull the timing case off one of the motors I have there. It would only be triggered once a rotation though so the engine really needs to be running

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| TimmyA |

|

|||

|

Just googled it... makes sense... looks at changing field and isn't binary like a hall effect... I can see the difference between them now... will try again tomorrow... You between the wires on the EF synchro you reckon there is 8V is that right? And I should be seeing similar?

The AU book shows the gear without anything on it to actually trigger the VR sensor... They got lazy... Cheers, Tim

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| misk_one |

|

|||

|

Lol I don't think there is anything specific on the wheel. I've puller a few aprt and never seen anything. I thought it might look at the chain and pickup a magnetic link?

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| TimmyA |

|

|||

|

Na couldn't do because the chain doesn't go around exactly once twice or three times to a complete motor revolution... It has to be in sync with the cam, and coincidentally the Aux gear has the same number of teeth as the cam gear and hence spins at the same revs so you can pick up off that instead... There has to be a metallic bar on the face of the aux gear and the more I think about it, it'd need to be 180degrees long... Otherwise the waveform would look like s**t...

Cheers, Tim

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| misk_one |

|

|||

|

the only difference i can see is the small raised dot on the gear. perhaps thats all its seeing.

AU:  earlier: unless it looks for the gaps in the wheel but that wouldn't actually tell the computer anything lol

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| misk_one |

|

|||

|

f**k if it does use that as a trigger then the EF cam sensor would needed to be modded to replicate anything close to that signal and it would need to be timed correctly id think.

i really need someone that has an AU to let me put the EF sensor in and let me see if it runs.

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| misk_one |

|

|||

|

i'd say that little dot is what it sees.

i just did some more reading of some info i'd read in the past and it jogged my memory a bit. the sensor is to tell the ECU where the start is in the 720* rotation as the crank will spin twice for every rotation of the cam. so that would all make sense. so, depending on how high the voltage is and where the AU sensor sits in relation to the dot at TDC (i'd assume the dot would signal TDC but it may be before) then i could just modify the EF sensor so that instead of having a complete 180* section it only has a very small section which passes through the hall sensor at TDC. would be easy enough to slip the sensor shaft in to the dizzy hole without the sensor itself on top which would allow for it to be positioned correction then attach the sensor.

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| misk_one |

|

|||

|

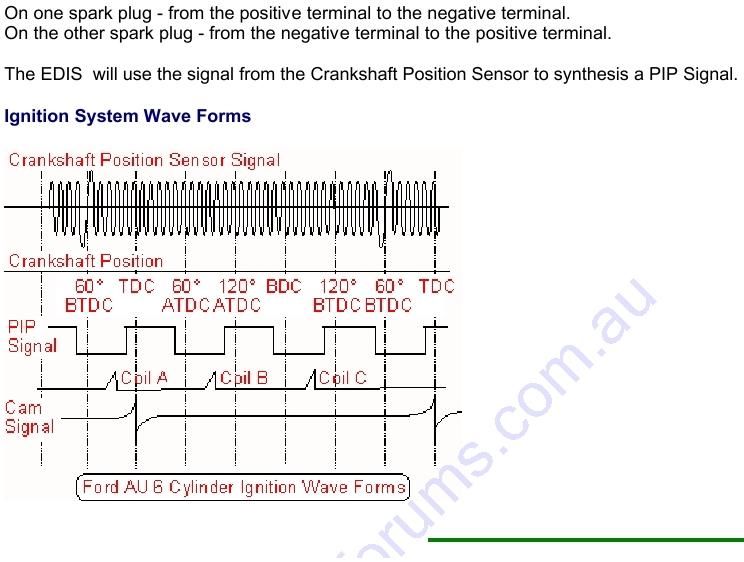

found this lil bit of info on the AU EDIS setup in this manual:

http://fordforums.com.au/wsm/wire/aued/CS01.html it has alot of good info on sensors and how to test them etc just not voltages lol still, its a great way of seeing how everything goes together. i think if the voltage is close enough it wont know the difference between a square wave and a sine wave just have to make sure the timing is correct.

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| misk_one |

|

|||

|

sorry for all the posts...

ive been looking for hours for BA falcon cam sensor values but cant find s**t! seeing as the AU ECU will run a BA engine using the BA cam sensor, perhaps if we can find the values it gives then that will help answer the question... i know its still a VR sensor but does anyone know the voltage range?

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| TimmyA |

|

|||

|

Yep... That Au motor you show appears to be that close to TDC it's not funny and where that lug is, is bang on with the sensor... So it is nothing like a sin wave coming out in this case... It's like that chart you showed where flux spikes as it goes past and then does nothing....

If the EF syncho has 180degree window in it then you'll be doing well to get that window exactly the right width and in the right position (TDC is a nothingness and that lug is what 4mm round, so is the centre of it TDC or one edge of it TDC?) Tell you what but, dropping an AU motor in is looking fairly easy in comparison... Cheers, Tim

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| misk_one |

|

|||

|

It has to be a sine pulse so to speak. There is no way it could get a value less than what ot has in the middle of those waves so that pic above dpesnt seem correct.

I would hazard a guess that it would just need to see over a certain voltage so as long as the ecu gets a spike at tdc it should be fine. I make these assumptions cause the dohc engine works and I doubt it would be getting the same values other than a similar wave pattern and the same position in the stroke. I'm basically happy enough to proceed regardless If any disagrees with my theorys shout out

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| Who is online |

|---|

Users browsing this forum: No registered users and 29 guests |