|

| scotty-williams |

|

||

|

hi all i have a eb11 fairmont with 200,000 onit i have a spare fullmotor that i want to rebuild to get as much power as possible while being reliable with the aid of any forced induction

what can i do to the motor what size? pistons bearings cam spec? valves etc any help will be good |

||

| Top | |

||

| EA-SPAC-88 |

|

||

|

{USERNAME} wrote: hi all i have a eb11 fairmont with 200,000 onit i have a spare fullmotor that i want to rebuild to get as much power as possible while being reliable with the aid of any forced induction what can i do to the motor what size? pistons bearings cam spec? valves etc any help will be good I'm getting a n/a engine built and my pistons are 30 thou over, I got the block hot tanked, bored and honed to suit, bearings ate 10 thou under, decked to 0, crack was ground and linished. Rods shot blasted. And now I'm getting a hoppers reco performance head shaved 30 thou off with a 977b wade cam. It's also a ef block. The auxiliary shaft needed replacing also. The machine work cost me around $1500, the rebuild kit with head bolts was $640 |

||

| Top | |

||

| the sam |

|

||

|

Here is a quote from myself from another thread:

I put a reasonable list together which should be good for around 350-450rwkw with reliability in mind and it came to around $10g just turbo parts. Then theres the engine side, which will need to be rebuilt if youre looking at ~300rwkw+ consistently. Here is my list with rough quotes on what i could find net prices of: (some parts missing) Billet turbos SB70GT-Q ball bearing turbo - $???? (assuming around the $2g mark) Custom long runner manifold - $500 on ebay Plazmaman Plenum - $1445 (depends on finish) Plazmaman 680x340 swept back front mount - $1240 OR Plazmaman water to air cooler - $1255 (requires more parts to fit) 2 x Bosch 044 external pumps - $240ea 2L surge tank + fittings - $250 Then theres the extras: Braided fuel lines - $??? Braided oil lines - $??? Oil fittings + oil surge tank - $200-300 50mm Wastegate - $500-800 BOV + intake plumbing - $500+ Then theres the exhaust side: I was thinking twin 2.5" to keep muffler prices down. Will still have to be custom made so - $1500+ Then theres the engine side too: Full Spool engine rebuild kit - $2390 Balanced, hardened crank - $200 Cam - $400 Headwork - $1500 (including valve work and valve springs etc) Then youve got to find someone to do all the engine assembly work (if you dont do it yourself) - $2000-3000 depending on time Then theres all the miscellaneous s**t: ECU Tuning Dyno time Replacing broken parts (if something does let go) Battery relocation Wiring Tools Filters Hoses Fittings Pipe Welds It goes on and on and its good to know what sort of money youre looking at before you dive into the deep end. The supercharger path ends up a fair bit cheaper, but youre not chasing these sorts of numbers. The eaton charger route would pull up under 10k easy with tune done and the water/meth injection also. Looking at numbers around the 300rwkw with this money. Remember, youre still going to need to rebuild the motor to cope if youre looking at these numbers... BIG MONEY Check out Fritzz build thread on boostedfalcon to see what he did to get his incredible result. i think its something like 540rwkw running the billet turbos sb70gtq.

_________________ LOW, LOUD AND LUMPY |

||

| Top | |

||

| Troy |

|

||

|

if you staying na i wouldn't touch the bottom end if in good nick, just get the head done.

it's just not worth it unless your chasing big power |

||

| Top | |

||

| the sam |

|

||

|

{USERNAME} wrote: if you staying na i wouldn't touch the bottom end if in good nick, just get the head done. it's just not worth it unless your chasing big power Exactly, your bottom end will easily hold 250rwkw which is probably more than you'll reach na anyway. Plus your gearbox, diff and brakes all cost money

_________________ LOW, LOUD AND LUMPY |

||

| Top | |

||

| tickford_6 |

|

||

Posts: 6449 Joined: 11th Nov 2004 |

It will make more power on a fresh bottom end.

|

||

| Top | |

||

| the sam |

|

||

|

{USERNAME} wrote: It will make more power on a fresh bottom end. Cost vs gain though?

_________________ LOW, LOUD AND LUMPY |

||

| Top | |

||

| DRHEMI |

|

|||

|

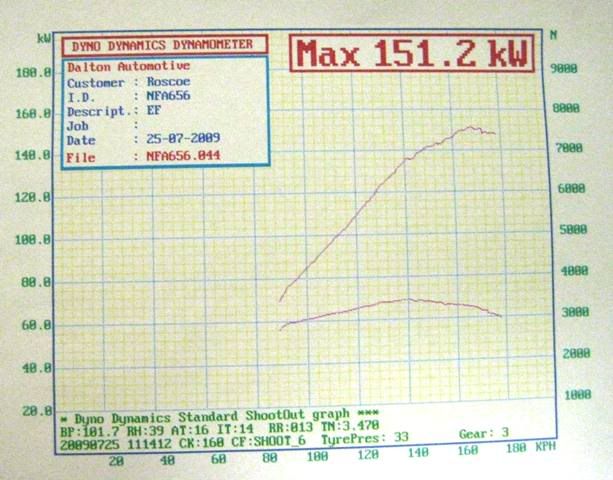

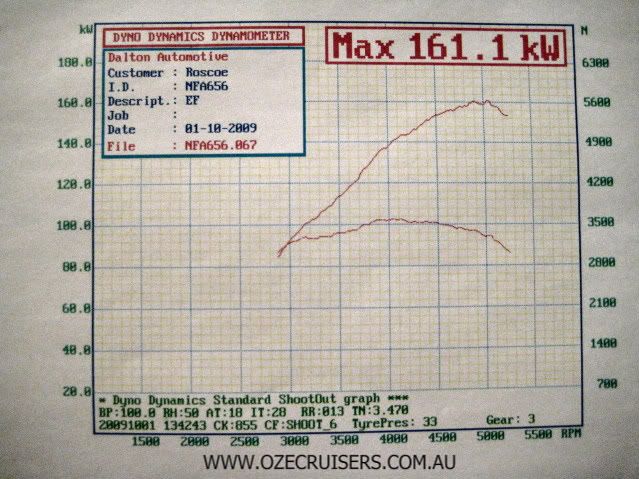

Back in Oct, 2009 I got 10 more rwkw with a rebuilt bottom "stock" bottom end

That was with just a Hone, new bearings & rings - block was not decked I re-used the Same Pistons, Rods, Crank, Block, head etc etc - basically a freshen up

_________________ PROEF 13.46 @ 105.78mph - 1994 Ford Fairmont EF NA 6cyl Man 3.9 diff Sedan |

|||

| Top | |

|||

| EA-SPAC-88 |

|

||

|

{USERNAME} wrote: It will make more power on a fresh bottom end. I'm not sure what mine will make, ill just have to wait and see |

||

| Top | |

||

| Greenmachine |

|

||

|

Over the last 15 or so years I've done all the usual stuff to Falcon I6.

The BIGGEST noticeable difference to POWER was from fitting a CAM. The BIGGEST noticeable difference to overall PERFORMANCE was from fitting a high stall converter (ie. GREATER improvement - by feckloads I might add - than converting to manual...) WHICH cam to go with is another question - I personally use a JMM cam which I believe is something similar to Stage 3 Hi Lift (got it before they actually had commercial grinds sorted - mine is one of their early development grinds) - the big thing about it is not it's outright specs but it's PROFILE - which works tremendously with the std ECU which equals great NOTICEABLE throw-your-head-back power increase AND terrific fuel economy. This thing needs about 3.5mm of extra shimming (it's a regrind) yet WILL idle with a std ECU - in an ED it prefers an XR6 ECU (is quite a head turner with a std ECU as it spits and ferts like some wild dragcar) but in an EF it's happy with the std ECU or XR6 one.

_________________ Sold the Greenmachine - now driving 2015 Jeep Cherokee Trailhawk. |

||

| Top | |

||

| EA-SPAC-88 |

|

||

|

{USERNAME} wrote: Over the last 15 or so years I've done all the usual stuff to Falcon I6. The BIGGEST noticeable difference to POWER was from fitting a CAM. The BIGGEST noticeable difference to overall PERFORMANCE was from fitting a high stall converter (ie. GREATER improvement - by feckloads I might add - than converting to manual...) WHICH cam to go with is another question - I personally use a JMM cam which I believe is something similar to Stage 3 Hi Lift (got it before they actually had commercial grinds sorted - mine is one of their early development grinds) - the big thing about it is not it's outright specs but it's PROFILE - which works tremendously with the std ECU which equals great NOTICEABLE throw-your-head-back power increase AND terrific fuel economy. This thing needs about 3.5mm of extra shimming (it's a regrind) yet WILL idle with a std ECU - in an ED it prefers an XR6 ECU (is quite a head turner with a std ECU as it spits and ferts like some wild dragcar) but in an EF it's happy with the std ECU or XR6 one. do you know what that cam is in equivalance to wades re grinds? |

||

| Top | |

||

| Greenmachine |

|

||

|

From other people's comments I'd say it's roughly similar to a Wade 1673 - and I have to say that without having tried a 1673 I'm not making any comparative claim about my JMM cam - for all I know the 1673 may completely hose this cam down - my point is that compared to the tiny improvements you get with the other std stuff like intake and exhaust, the improvement that a good cam can make is HUGE. BUT - to get the best out of a cam of course the intake and exhaust do also need to be done.

I have run this cam back to back with a Crow 2222529 (pretty sure it was 529 but it may have been 525) and it definitely goes waay better than that (the Crow cam made good torque but was slow to rev) - but the Crow cam was obviously really not working very well with the ECU so might well have been much better with aftermarket ECU or a J3 tune - again the great thing about the JMM cam is how well it works with no management changes. In the context of other mods like intake, exhaust etc. - I've currently got the JMM cam in my otherwise stock EF engine (ie. I still haven't got round to doing the exhaust - it's still factory press bent 2.25 with factory cat and iron manifold) - and the car noticeably picked up power and responsiveness as well as a huge improvement in fuel economy - but only up to about 4000rpm or so at which point it tends to thrash and not really go anywhere - which is no surprise with the factory exhaust. Redback system, 2.5 cat and some Tiger headers are going on soon. By comparison, on my original Falcon I fitted K&N Filter and did the exhaust first and it was a case of certainly felt no worse and I guess maybe felt better - particularly at higher revs - but real NOTICEABLE improvements didn't come until I started messing with the cam.

_________________ Sold the Greenmachine - now driving 2015 Jeep Cherokee Trailhawk. |

||

| Top | |

||

| Greenmachine |

|

||

|

My original car was a 93 ED that ended up with EFXR6 Head, ELXR6 ECU and BBM - with both BBM switching and knock sensing wired in and working from the ECU.

Before getting the EL ECU all working, I ran the BBM just locked on long runners except for specifically testing top end - BBM on short runners KILLS the bottom end!!! (way more than long runners hurt the top end). As far as cams go I started out with EDXR6 cam before the BBM went on and then once the BBM was on I experimented with advancing a std cam by one tooth (about 4*), advancing the EDXR6 cam by one tooth and then welding and recutting the notch in the EDXR6 cam to it was about half of one tooth advanced. This was all before adjustable cam gears were available for I6. Std cam advanced one tooth would be my pick for a great daily driver or taxi - bottom end / midrange were very nice and fuel consumption improved drastically but it ran out of go well before 4000rpm. To be honest I don't know why std Falcons didn't come from the factory like that: for all normal driving - including normal highway cruising - it was perfectly fine and felt very much like a VN Commodore but with much more torque. It would have made the performance of XR6 much more distinctly different too - I think they dropped the ball badly by making std cars too much like the XR6 and not as well suited to normal and town driving as Commodores. Holden have shown much better understanding of real world needs in that respect I'm afraid. Advancing the EDXR6 cam gave predictable results - ie. similar to doing the same with the std cam but top end held up somewhat better (still badly affected tho). Fuel economy improvement wasn't as great as with the std cam. The moved notch on the EDXR6 cam worked very nicely and I used that for quite a long time - until I got the JMM cam and it became permanent. Along the way I tried EF std cam EFXR6 cam and the Crow 2222529 cam - all on std timing. Finally I got the JMM cam and it's the one I've been using since. BBM switching from the ECU came after the JMM cam went in, but with the other cams altho I always had the BBM locked on Long runners for daily driving I did try each one with it on short runners as well - so was able to see top end too - but not at the same time as having long runners for bottom end. As far as cam timing goes, my general observation is that retarding cam timing affects the bottom end less than advancing affects top end - in short, timing changes affect the top end across the board more than the bottom end. In it's final form that car did 4 trips between Broome and Cairns without missing a beat - it could cruise quite economically at 130 (about 600km to a tank from memory) - was perfectly happy to run at 180 all day if you wanted too but it drank fuel bigtime above 130 (2300rpm +). I could follow another car at 180 or so and comfortably pull out and blast past - WITH my car and boot loaded to the point where it was just about on the bumpstops... Bilsteins of course made it all possible

_________________ Sold the Greenmachine - now driving 2015 Jeep Cherokee Trailhawk. |

||

| Top | |

||

| Who is online |

|---|

Users browsing this forum: Facebook [Bot], Google Adsense [Bot] and 67 guests |