|

| Shifteh |

|

||

|

hell while we are at it i was thinking upgrading to larger chips and having basically all mods in one box,

Auto window wind up on lock,? shiftkit? alarm system?? Coded Entry? automatic Intruder melting device ( Lol jokes) Engine: Each cylinder temprature monitering Oil temp Water temp and FLOW Infra-red sensor attached to serpentine belt with reflector ( like shop ding dong things) to detect if belt is broken the list goes on, the possibilities are endless and awsome we could run lcd screens anything

_________________ Crank Assembly balanced, HV oil pump, ACL Trimetal bearings, "1 extra oil clearance taking to around 0.0650-0.0700 on mains and big ends, Moly rings,, Xr6 Cam, POD ( Possibly oversize injectors), Block, Head, Timing cover, belt idler, Alternator,painted in ford light blue |

||

| Top | |

||

| misk_one |

|

|||

|

well i got the code alot more stable after finding some better coding programs.

i'll have to choose a different PIC to the one i was going to use so as to accept an analogue signal (ie. from the shifter on the box), the program will be able to accept either the signal from the shifter or from two buttons - but not both at the same time, i don't think i can write the program to accept an input from the shifter AND have control through the button inputs, so might be a case of either of the two depending on preference. i will most likely be able to rig it so its all contained in a small box with a loom with plugs for 12v/ground, up/down gears, shifter signal, and S1/S2/S7 solenoids. don't know what else is worth looking in to? any other suggestions? remembering i'm only going for a simple setup...

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| Nigel |

|

||

|

Write your code so that it accepts the analog signal from the shifter until it receives a signal from a button..... then it can change over to buttons as long as the shifter is still in (1-D)?

|

||

| Top | |

||

| misk_one |

|

|||

|

thats what i've done, but what i mean is it will be a bit hectic to write the code so that say you shift into 3rd using the shifter, then go down to first using the buttons, then change into 4th (D) using the shifter, i would need to include alot more code

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| Nigel |

|

||

|

Nah - stay on buttons, and a select "N" to reset back to the shifter..... or D to reset back to shifter

Either way. |

||

| Top | |

||

| misk_one |

|

|||

|

that doesn't make any sense man.

if you put the shifter into N it will go into neutral, thats controlled manually by the box.

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| Nigel |

|

||

|

Correct - so your driving, playing with the shifter... you get serious and start playing with the switches. When you want to go back to stick (finished playing, most likely pulled up)... into neutral.

Otherwise it would make sense that you need to put the box in 3, 2, or 1, and use switch to activate. you can go back to normal by putting box in D. Because of the detents you can put the car in D without using the detent button. Its not likely at all that youd change mid-spirited drive |

||

| Top | |

||

| misk_one |

|

|||

|

still doesn't make sense lol

you can't code it so you can use the switches and the shifter at the same time. i dont think you quite understand what i'm aiming to do with the code. what i'm making can be run 100% independent of the standard ECU to control up/down gear sifts. if you have some experience with coding, please try and explain it in a more logical way. it can be written that you can change gears manually with the shifter, then swap to the buttons and swap back again through input of another button (or if you wish, Neutral), but it will be 100% manual the whole time, not like shifting like a normal setup. i could have misunderstood you though

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| AaronDTM |

|

||

|

Hello,

I stumbled across this thread and thought I may be of some assistance. I have 2 cars running manual shift BTR's, 1 has push button shifting as well as shifter, the other is transbraked. Yes this is true. I designed it. When going about using the S1 and S2 solenoids only, there needs to be modifications done to the internals of the transmission or you run a seriously high chance of breaking the overdrive shaft inside the trans. You must also activate the S6 solenoid at low throttle positions ie. less than 2-3% or the pressure plate on the C2 clutch can blow out of the input clutch drum destroying the transmission when shifting from P/N to D. We use Motec and Autronic to control the engine and transmissions via the gear position switch. I have run 11.5 in the ute and the turbo sedan has gone 9.80 off the transbrake with a 1.48 60'. These autos have potential if built and controlled correctly. Without the mods the 1-2 shift will be EXTREMELY violent. It doesn't really matter what method you use to control the solenoids as long as the S1, S2, S6 solenoids are used as well as the internal transmission modifications. Hope this helps a bit. Kind regards Aaron DTM automatic transmissions Geelong |

||

| Top | |

||

| Vic |

|

|||

|

Wolf have finished programming their v500 to run the V8 BTR auto trans a little earlier this year and I'm running their program in my car and everything is adjustable via the laptop in realtime. Works perfect. From memory, Robbie said they already have customers with the 6 cyl using their auto programming.

_________________ 5.6L of carbon footprint. |

|||

| Top | |

|||

| misk_one |

|

|||

|

{USERNAME} wrote: Hello, I stumbled across this thread and thought I may be of some assistance. I have 2 cars running manual shift BTR's, 1 has push button shifting as well as shifter, the other is transbraked. Yes this is true. I designed it. When going about using the S1 and S2 solenoids only, there needs to be modifications done to the internals of the transmission or you run a seriously high chance of breaking the overdrive shaft inside the trans. You must also activate the S6 solenoid at low throttle positions ie. less than 2-3% or the pressure plate on the C2 clutch can blow out of the input clutch drum destroying the transmission when shifting from P/N to D. We use Motec and Autronic to control the engine and transmissions via the gear position switch. I have run 11.5 in the ute and the turbo sedan has gone 9.80 off the transbrake with a 1.48 60'. These autos have potential if built and controlled correctly. Without the mods the 1-2 shift will be EXTREMELY violent. It doesn't really matter what method you use to control the solenoids as long as the S1, S2, S6 solenoids are used as well as the internal transmission modifications. Hope this helps a bit. Kind regards Aaron DTM automatic transmissions Geelong thanks for the info. i was more aiming to create just a manual controller that would be used with the standard ECU still in place, so control over S6 isn't a issue in that sense, but i can easily write code for that function anyway. i've also added code for LCD out to show which gear selected. i found with the standard ECU still in place and just controlling gears manually through S1/S2 the shift was firm enough even without any other other mods, as the ECU doesn't know its about to change gears there is no dampening or softening of the shift through control of the S3-S5 solenoids. is the transbrake mechanical in the way it operates, or is it something that can be manipulated electronically?

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| misk_one |

|

|||

|

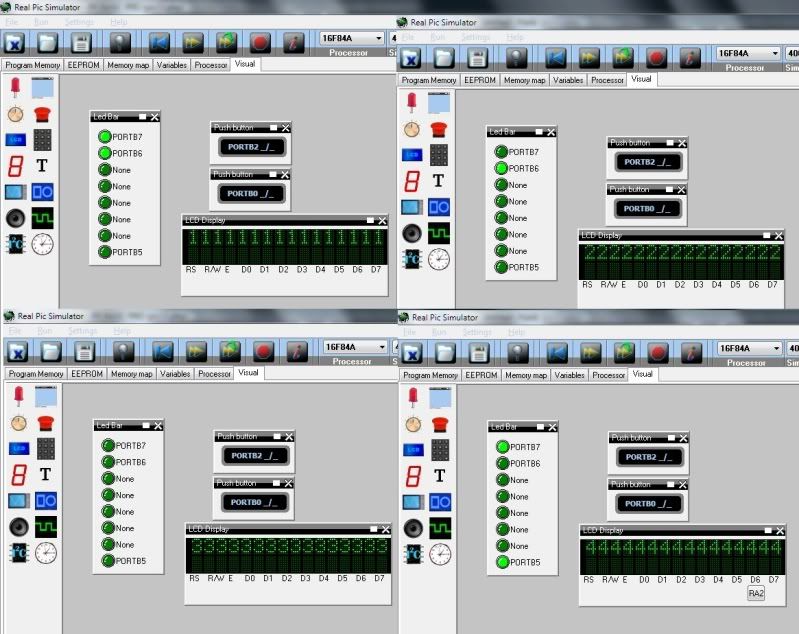

just to give you a rough idea of the program that i coded and what i was aiming for...

as it will be combined with the standard ECU as i mentioned above the solenoids will be active, but not able to prepare the box for shifting (ie. slowing and smoothing the gear changes) but i felt that lockup in 4th can be permanent, without the PIC powering S7, the standard ECU will still be able to do so at 80kph as per standard - i may add a button to trigger whether the ECU controls it or the PIC. the green LEDs represent the S1/S2 solenoids at the top and S7 at the bottom, while the button windows represent up/down shift buttons

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| AaronDTM |

|

||

|

This is very similar to some controllers we made about 6 or 7 years ago. We had the LCD readout as well. The issue I brought up in my last post is just durability problems that will arise without the use of the S3-S6 and internal mods. There is a design flaw in components inside the transmission that will cause failures when not using the S3-S5 under heavy throttle shifts, although you may not see this unless you have substantial engine power. It is possible to break the band on the 1-2 shift and the shaft connecting the C1 clutch to the planetary carrier on the 2-3 shift. I broke the shaft in early testing and have since fixed the problem. The S6 controls the high and low line pressure. Without it on when you engage D, the fwd clutch can come on too hard in high pressure mode and break the input drum. This is less likely than the shaft breakage though. Keep going with your development because it does work in the end.

The transbrake is hydo/mechanical. It works unbelievably well but requires a full transmission build. Regards Aaron |

||

| Top | |

||

| misk_one |

|

|||

|

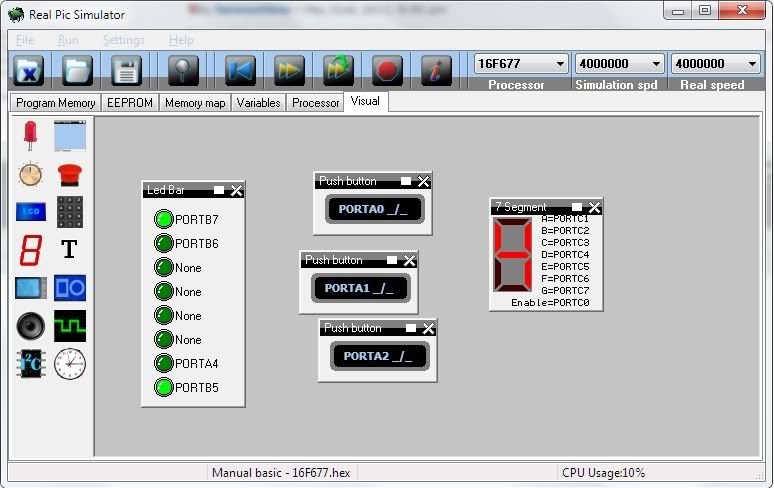

i ended up changing the code so as to output the gear in use to a seven segment LED and cleaned up some of the other code.

when in forth i have it setup so if there is an input from the button on PortA.2 (ie just a toggle push button) it will lockup the converter always when in forth. i'm not sure if it will effect deceleration, if so i will write so code so that it isn't active on decel using a signal from the TPS. next thing for me to work on is reading the signal from the inhibitor on the gearbox to allow proper use of the S6 solenoid and look at changing to manual mode whilst already moving - ie. if your in 3rd in D and switch to manual mode the gear will match what was read from the inhibitor and then control will be done through up/down buttons/paddles/whatever. in the future i'm looking at having ad option for lockup on decel for all gears like in a manual car im hoping to have a working unit in around 3 weeks. with different LCD:

_________________ {DESCRIPTION} |

|||

| Top | |

|||

| turbotrana |

|

||

|

There is a good article in Street Machine November 2009 with AaronDTMs input on Beefing up the BTR.

Definately worth a read. Aaron, you talk about the BTR weaknesses in that article and in particular you change the front servo piston to try to prevent front band breakage to name one. Do you sell any of these bits and pieces that we can fit to the BTR to improve its strength. I wouldnt mind getting one of your machined front servo pistons. Is this the mod to reduce the harshness of the 1 to 2 shift when running just S1 and S2 solenoids.

_________________ Turbo 6s rule |

||

| Top | |

||

| Who is online |

|---|

Users browsing this forum: No registered users and 24 guests |