|

| RohCR |

|

||

|

Update on fitting AU 1/2/3 injectors into my 3.9L EB1:

My EB1 has a stock factory computer as far as I am aware. The Bosch AU 6 cyl injector has 14mm O ring, flows at 200cc@3 bar and is high impedence. It also a slighly smaller overall body than the single nozzle OE injector. The box bar code reads as 12345003290. I can't say for sure this is a Bosch part number. Fitting was straight forward, IMO easier than the originals. This may be due to the more slender AU injector body? Now the warm starting sequence with the AU injector in my car is: key on, start, an initial idle up to about 1000rpm, a quick drop to about 750 rpm then settles stable at about 600rpm. This sequence is well defined and takes about 3 and a bit seconds. The computer seems to be quite able to manage successfully the AU injector. This sequence was not noticeable with the old injectors - If a sequence was there it maybe it was masked by a typcial 21yo car with old injectors and was more like: turn key, engine starts, there was a momentary low idle before the engine settled at about 650rpm. This took about 3 seconds - mostly but not all the time.. The idle before was resonable (to me) but not entirely stable like it is now. Overall power seems mainly unchanged both from standing start and rolling acceleration from 60kph. However, now throttle response seems "better", esp under light accelerator adjustments but also under full right boot when already rolling. The engine just feels smoother, more linear in its power delivery. There is some gentle clicking noises from the new injectors that was not there before. I can hear them clicking while standing next to the car with the bonnet down but I also don't have under-bonnet insulation anymore either. So, a round up... 1) Do I think it was worth the time and money to change to the AU injector? Yes. 2) Is it possible any improvements are just because the injectors are new and has nothing to do with the fact they are 4 hole nozzle AU units? Maybe but I think not - however this report is what my observations are. 3) Would I do the same on my Dad's car, or someone else's car if he/they wanted to put different/new injectors in and have me do it for them? Yes. 4) Am I going to dyno the car yet to "prove" or "disprove" any gains/losses? No - there isn't one in town anyway and I'd prefer to spend my money on something else. 5) Now to monitor fuel consumption and get some reasonable/longer term consumption averages I've been around engines and plant a long time now and I've done my share of mechanical breakdown, preventative and trouble shooting. I can say with confidence IMO the swap was worth it. EDIT: gratuitous pic

|

||

| Top | |

||

| RohCR |

|

||

|

Cooling System:

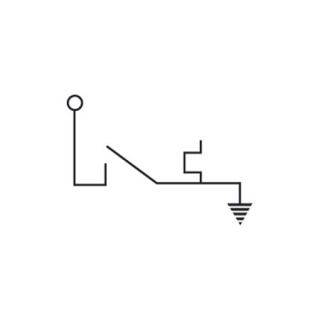

Object is to replace all hoses esp those pesky hard to get to ones, change thermostat from factory 90 degree to 85 C, change thermostat housing, change reservoir, add automatic thermo fan switch, general corrosion check on steel pipes: summer is a comin'. I didn't use an additive flush. I used a pH strip to test the coolant. It was a score of 7 (neutral). The inside of the various water ports seemed in good nick with almost no deposits, so the coolant has been changed regularly I'd say. Acid based flushes seem like a gamble as I'm not ready to disturb the head yet - leave sleeping gaskets lie? Some of the hoses were noticeably bulged and looked like they had never been changed in 21 years.... I bought a new Kilkenny Castings thermostat housing (WO49) and had it drilled/tapped to take a Tridon thermo fan switch {DESCRIPTION} If its all to hard to click the link, the specs are: TFS111 Fan switch Thread - 3/8 GAS Circuit - Normally Open Ground Temp Range: 95ºC to 90ºC Spanner - 21mm Circuit diagram is as follows:  So the thermostat opens 85C, temp reaches 95C, fan go on, then off at 90C. I'll be using 50% concentrate and de-mineralised water which should give a boiling point of 115C @ 96kpa, or so the expert tells me. I'll gladly be corrected. There was no room left on the thermostat housing base, all ports were used and I needed the fan switch to be as close to the thermostat as practical. The end result looks like this after drill/tapping the housing. I'll be epoxying the sender in:   So all the hoses came off and some of the steel pipe ends were rusted on the outside where the hose clamps on. I used a little acid based CLR Liquid and a toothbrush to clean them up. After rinsing off I treated the cleaned but still slightly rusty ends with Ranex Rustbuster (Bunnings). It is a Phosphoric acid that converts rust to a stable compound. Ebay supplied a new coolant reservoir and the S Pak has a low coolant sender, so Its been sealed into place now.   Tomorrow comes hand contortions fitting the new hoses and clamps. PS: I'm figuring you ppl that are into engineering/machining/big mods probably think this stuff is all a bit *yawn*. I'm figuring a long term older car ownership is only as good/enjoyable as its basic foundations - hence all this "boring" bread and butter work/stuff. And this is a ongoing record - like a log book, so to speak. Go Well Roh. |

||

| Top | |

||

| snap0964 |

|

|||

|

{USERNAME} wrote: I used a pH strip to test the coolant. Good to see someone else uses them too.{USERNAME} wrote: Ebay supplied a new coolant reservoir and the S Pak has a low coolant sender, so Its been sealed into place now. Keep an eye on it if it's this fella - http://www.ebay.com.au/itm/110962208508 ... 1438.l2649{USERNAME} wrote: PS: I'm figuring you ppl that are into engineering/machining/big mods probably think this stuff is all a bit *yawn*. I'm figuring a long term older car ownership is only as good/enjoyable as its basic foundations - hence all this "boring" bread and butter work/stuff. And this is a ongoing record - like a log book, so to speak. Nah, not at all - good maintenance is always good to read.Use a bit of Silastic RTV blue instead of the epoxy - the heat will make the epoxy brittle over time.

_________________ 96 XH Longreach 'S': LPG, Alarm, 3.23:1 LSD, Cruise, Trip Comp, ABS, Power Windows, Mid Series Dome Lt, Climate Ctrl |

|||

| Top | |

|||

| RohCR |

|

||

|

Thanks for the encouragement mate - Cheers snap0964!

I checked the coolant reservoir that I got...they all look the same but mine had the language on pressure cap in German, as if that means anything? Auf means off? I'm keeping a private log on what I do on the wagon and I thought to copy and paste it below. There are so many sub-systems maintenance and catch-up that go into making an older car reliable. Remembering I got the car about 2 months ago and its a keeper for me and also I live far from any city. I hate walking. A hot and bothered for-all-the-wrong-reasons, stranded Wifey doesn't bear thinking about. However, things are going to slow down considerably...grain harvest will start soon and I won't have time for quite a few months. Anyhow here we go: Update Roundup on jobs progress August to End October 2012: 1) Kill switch fitted. 2) New door locks fitted. 3) Front windows (re)tinted. 4) Door cavity wind seals replaced. 5) Clean & service internal door locking mechanisms. 6) Front door sound insulation upgraded. 7) Sony Stereo - 6 speaker (under seat bass) 8) Heavy power to rear of wagon for Waeco Fridge & Inverter. 9) Carpets removed, washed & re-fitted. 10) Wagon rear tank/spare wheel cover hinged & struted. 11) Washer motor front & washer motor tailgate replaced. 12) Extra courtesy under dash floor lights fitted. 13) Fairmont thermo skinned console fitted. 14) Cargo Barrier fitted. 15) 6x AU injectors. 16) Auto serviced. 17) New plugs, leads, cap rotor & coil pack fitted. 18) Diff oil replaced. 19) Brake fluid replaced. 20) Engine oil & filter change. 21) 85c thermostat fitted & new housing, drilled/tapped to take Tridon Thermo switch. 22) EL twin electric thermo fans fitted and wired to 95c on - 90c off (no smartlock to control the fans on this model). 23) Complete change of all cooling hoses. 24) New coolant reservoir fitted. 25) 50% glycol coolant filled. 26) Complete change of all vacuum hoses. 27) Remove all previous fitted scotchlock connectors - solder & heatshrink replacement wire tap points. 28) Wiring looms tape re-wound and/or conduited & braced where appropriate or needed - esp. engine bay re: heat & age affected looms & connectors. 29) New (stock colouring) tailights. 30) New (orange) front indicators. 31) New L & R headlamps 32) Front of engine belts & idler pulley bearings changed. 33) New Falken 205/65/15 tyres 34) Wheel alignment Already fitted to car recently before purchase by previous owner: Genie extractors New exhaust New alternator New water pump New ball joints Potential problem areas: Steering rack - hydraulic leak? |

||

| Top | |

||

| snap0964 |

|

|||

|

{USERNAME} wrote: 27) Remove all previous fitted scotchlock connectors - solder & heatshrink replacement wire tap points. Yep, scotchies create more problems longterm than they fix.

_________________ 96 XH Longreach 'S': LPG, Alarm, 3.23:1 LSD, Cruise, Trip Comp, ABS, Power Windows, Mid Series Dome Lt, Climate Ctrl |

|||

| Top | |

|||

| RohCR |

|

||

|

Hi All

Back from the dead, things have been busy, you know, life Red EB Wagon update: {DESCRIPTION} The old banger has been earning its keep over the grain harvest period & summer generally. Have done around 15,000 k's in this time. All good up until about a month ago. A whole bunch of engine gaskets that were weeping oil got out of hand, the inlet gasket is now stuffed and lastly the power steering has now begun leaking through the switch body. What to do? Thought about it for a while before this but now I must do something or else. The Falcon needs some lurvin' Time to go exploring. Compression is good. So out with the engine. Onto an engine stand. Off with the head. Head is good. Off with the sump. Some oil varnishing but no metal. There is a bunch of new bits in the shed I've been collecting over time. Hmm, its what I call a half rebuild - leave the crank & pistons alone cos they're fine. Fix the other stuff. Here's a list of what been or being done at the moment: Not the Motor ~ 1) My local mechanic put a new steering rack & switch in, serviced the auto. 2) Detail engine bay, no paint but its a toothbrush job. 3) Re-wrap most OE wiring looms. Fabrication ~ 4) Build a chain block frame to lift the engine out. I used scrap form our local metal recycler. Fab a removable A frame. Put it on old 13" Holden rims and stub axles. Now its movable/towable with a light board - but not on a freeway. Though I'm sure my dumb bro in law would do that...(face palm) Motor ~ 4) New welsh plugs, visual check for amount of cylinder wall electrolysis. Acceptable. 5) Clean sump, pick up. 6) New rear main seal, new distributor/cap/leads, spark plugs, water pump, timing chain, head gasket, sump & any other gaskets, etc 7) Clean and paint block. Clean alloy parts internally/externally. 8) Clean & service throttle body, inlet manifold etc. 9) Replace suspect alternator regulator pack. Starter is fine. 10) Weld tabs onto Genie extractors to mount OE manifold heat shield - trying to stop heat radiating onto RH engine bay skirt and components like brake master cylinder. Heat soak has been a problem. 11) Relocate & re-wrap injector loom. The motor is back together now but not in yet, working on it in between everything else. Sorry for cruddy pic, phone camera lens needs a clean too. Corroded rear welsh plug. The one that's hidden in the bellhousing. Nasty. {DESCRIPTION} Motor together on stand. Put it in soon-ish. {DESCRIPTION} |

||

| Top | |

||

| snap0964 |

|

|||

|

Yeah, it's a good idea if you're doing the rear main to change that welch plug too.

_________________ 96 XH Longreach 'S': LPG, Alarm, 3.23:1 LSD, Cruise, Trip Comp, ABS, Power Windows, Mid Series Dome Lt, Climate Ctrl |

|||

| Top | |

|||

| Mad2 |

|

|||

|

lookin good!

|

|||

| Top | |

|||

| RohCR |

|

||

|

Thanks for the encouraging comments guys.

Added to the list this morning: 12) 2 x engine mounts I was between sixes and sevens over a half rebuild. Its the cost factor of a full rebuild. But if the basics are good? Question if anyone wants to have a stab at it: Since the corrosion/electrolysis inside the motor was acceptable and the rear welsh plug was fairly well corroded...see pic above... Can welsh plugs act as a sacrificial corrosion point? This was an OE steel plug. |

||

| Top | |

||

| snap0964 |

|

|||

|

I suppose they can, usually the less 'noble' metal will corrode to sacrifice itself, e.g. zinc blocks.

I guess in a car's cooling system, alloy components would be at most risk. Replacement welch plugs I've seen are usually brass, they're reasonably high up the scale - with glycol based coolants, I think they're designed to minimise electrolysis, hence using straight water is the best recipe for corrosion.

_________________ 96 XH Longreach 'S': LPG, Alarm, 3.23:1 LSD, Cruise, Trip Comp, ABS, Power Windows, Mid Series Dome Lt, Climate Ctrl |

|||

| Top | |

|||

| Who is online |

|---|

Users browsing this forum: No registered users and 185 guests |