|

| huggiebear |

|

|||

|

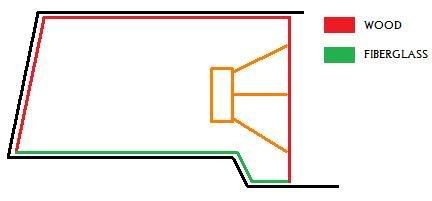

hey all. im going to be building a new sub box, however i want to fiberglass the bottom to flow with the boot. now the problem i have come across is once i fiberglass the bottom of the box, how do i attach it to the rest of the box?

do i extent the bottom under the front board and screw it into the front panel? or do i make a lip on the inside? how has everyone else done it?

|

|||

| Top | |

|||

| MoNGooSE |

|

|||

|

Hey man.

Instead of going to the expense and trouble or fibreglassing... why not just make up a false front to screw onto the front of the sub box? That's what I'm doing at the moment. It's heaps easier than fibreglassing and it ends up looking real nice with a bit of care... Have a look at some of the setups in this thread: http://www.fordmods.com/forums/viewtopic.php?t=11289

_________________ EF GT6 - 129.4rwkw - Feautured in Street Fords Issue #77 |

|||

| Top | |

|||

| huggiebear |

|

|||

|

i am actually talking about the greenline on my diagram, not the boot floor itself.

i already have the flat floor sorted out |

|||

| Top | |

|||

| MoNGooSE |

|

|||

|

Hmm... I understand what you're saying... What I meant was, instead of shaping the bottom of the sub box down to the floor, why not just build your sub box to fit in under the parcel shelf behind the seats and fix it there nice and solid and then attach a false front to the sub box which goes right down to your floor and right up the the parcel shelf so that it looks like your sub box is fitted in there nicely when really it just appears that way due to the false front which covers any ugliness of the sub box.

Has that made any sense? That's what I did anyway. You've seen my install

_________________ EF GT6 - 129.4rwkw - Feautured in Street Fords Issue #77 |

|||

| Top | |

|||

| huggiebear |

|

|||

|

yeah i see what you mean now... i had a blonde moment lol.

thats how i have decided to do it. however i dont want it to look like the subs are sitting really high. im thinking of the space inderneath the subs ill run the amp wire across as ill be splitting it up, 4g from left till the middle, then a distro block and 4 g up to the amp and 2 runs of 8g off to the right yeah i saw youe install. looks good |

|||

| Top | |

|||

| pyroay |

|

|||

Age: 44 Posts: 2121 Joined: 14th Dec 2004 Ride: FG Turbo Territoty Ghia Location: Traralgon |

If you want to build one the way you have shown in your diagram.

Build the fibreglass bass with a small piece of plywood or mdf sticking upwards on the baffle wall (around 150mm high). Then you have easy access to work over the top of it for the laying of the fibreglass and you have something to mount the fibreglass to. When you have a solid connection build the compelte baffle piece you wish to use and working through the sub hole you have cut out screw the small 150mm piece to the baffle plate. You can do the same with the backpioece and will end up with a very solid box.

_________________

|

|||

| Top | |

|||

| huggiebear |

|

|||

|

cheers for the advice. altho it looks like ill be using MDF in the end. cost wise vs ease, the MDF wins in the cost department.

i do want to fibgerglass the panel to bring the subs out a little just for something different. bring it out about 2 inches and fiberglass it smooth. i have learnt alot from my last fiberglass job (dont buy it from bunnings, go to a propper mob and get a thinner more workable sheet and more resin well my holiday is just over a week away so it will ge all go go go when i return. |

|||

| Top | |

|||

| Who is online |

|---|

Users browsing this forum: No registered users and 31 guests |