|

| B Bear |

|

|||

|

Got a few things done today...

Fixed up the gap on the spark plugs as recommend by Troyman to .7 - .8 mm  Took off the extractors to mount up the log manifold  Another picture of the capped off oil return line with everything out of the way  Manifold with new slimmer gasket in the back  Waste gate and pipe attached, want to get that plumbed back into the dump pipe  Manifold now on the car

|

|||

| Top | |

|||

| B Bear |

|

|||

|

Also put in some chrome rocker bolts that we got off a friend.

|

|||

| Top | |

|||

| B Bear |

|

|||

|

So there were two spots on the manifold where there was a bit of weld overlap. This meant that the bolts for these spots weren't taking up properly.

Got some different bolts and washers which worked great and also fixed up the most problematic spot at the front with a dremal. Bolts....   Worst affected...

|

|||

| Top | |

|||

| B Bear |

|

|||

|

The turbo was also fitted on the manifold today whilst in the car to test out the pipe across the throttle body. Everything fits quite nicely and no cables or pipes seem to be in the way hot side of the turbo.

Question though... We need to pick up a reference point for the wastegate and were going to put in a barbed fitting on the red mark. This has all been discussed in the wastegate thread I created a little while back. Just wanting to confirm as it is a lot easier to install the connector into the pipe rather than the compression housing of the turbo. Seems to be about the same if it was to be in the pipe rather than the compression housing as it's direct to the TB and not having to pass through lengths of pipe or an intercooler. Excuse the mess...

|

|||

| Top | |

|||

| TROYMAN |

|

||

|

if your not wanting to drill and tap the compressor housing, then the next best place would be where your red dot is...

|

||

| Top | |

||

| B Bear |

|

|||

|

{USERNAME} wrote: if your not wanting to drill and tap the compressor housing, then the next best place would be where your red dot is... Thanks Troyman, that's where it will go then |

|||

| Top | |

|||

| B Bear |

|

|||

|

Bit more work on the car yesterday...

The turbo is now properly bolted up and different lines being connected. Just a quick shot of the turbo..   Oil return line is now connected up as well.  Manifold heat shield is now on too, might need a little polish once all done.

|

|||

| Top | |

|||

| B Bear |

|

|||

|

The oil feed line in the kit was way too long it was able to be connected to the sender unit and extend past the car.

So we had to fix this up as we didn't want any crimps in the line. We got a new end piece for the oil line and cut off the extra length. Connected up to the oil sender unit.  Connected to the top of the turbo.

|

|||

| Top | |

|||

| B Bear |

|

|||

|

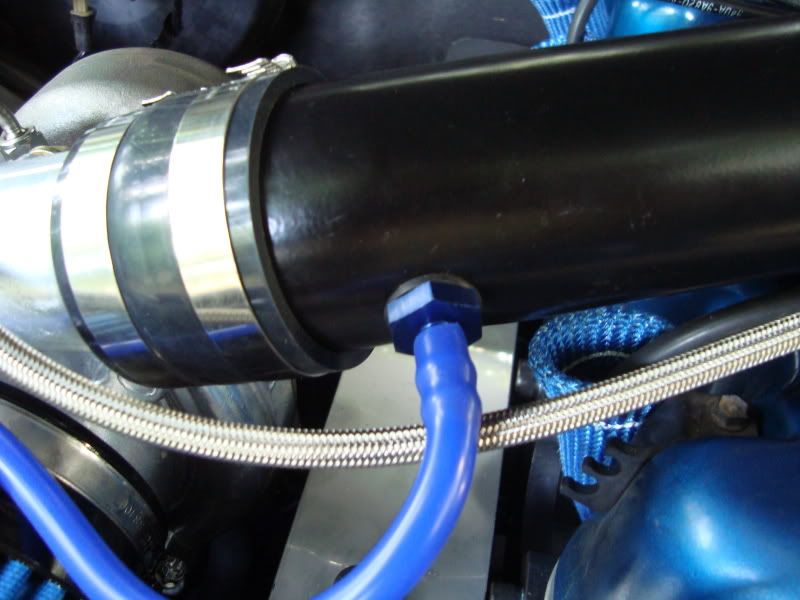

The engine bay is looking much cleaner now, we also got some heat shield boots for the leads and plugs...

Connected up the throttle pipe too.

|

|||

| Top | |

|||

| B Bear |

|

|||

|

With the supplied pod filter it just wouldn't bloody fit ! The clearance to slide it past the power steering pump and onto the compression housing was about a centimeter or two off. It would have gone on if we took the turbo back off put then put the pod on whilst off the motor, but stuff that !

So we picked up a shorter drift pod filter which tied in nicely with the colour of the engine bay. The wastegate vac line is now also connected, with a barbed piece taped into the pipping to the TB.     So now all that needs to be sorted out is the exhaust, fit the catch can and get the car tuned again on the J3 chip. |

|||

| Top | |

|||

| B Bear |

|

|||

|

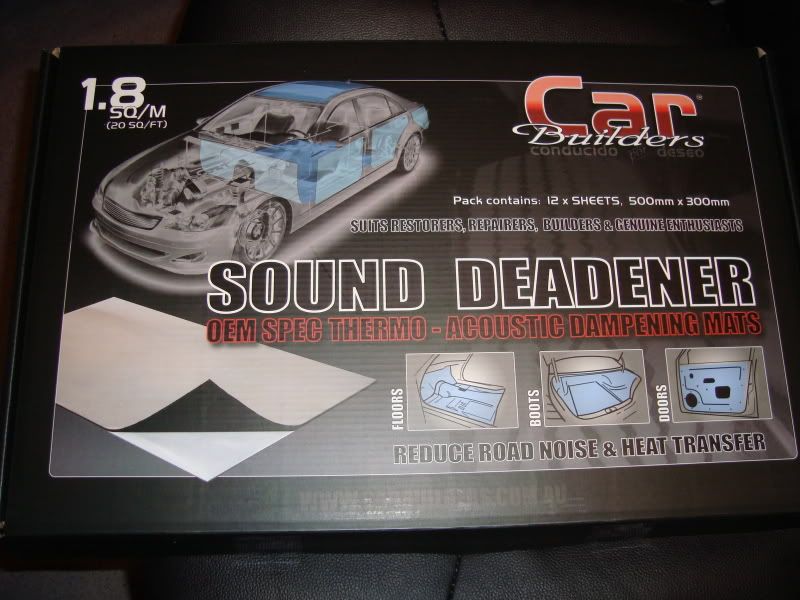

Something I did a little while back was sound deaden the boot lid. I was sick of the god awful boot rattle.

Decided to try some of the cheaper stuff from ebay and it has worked just as good ! Also added in some expandable foam into the beams of the boot.    My good did it add some weight to the boot lid, although it did reduce a lot of the rattle and feels like there is more bass in the cabin. I might even put some on the parcel shelf. Luckily the carpet covers all this up so it looks much cleaner.

|

|||

| Top | |

|||

| galapogos01 |

|

|||

Posts: 1139 Joined: 27th Feb 2005 Ride: Supercharged EF Fairmont Location: T.I. Performance HQ |

Nice work on the turbo install, very neat job you're doing.

Get a Fairmont boot lid carpet and that sound deadener job will come up mint. I did the same thing to my EF about 7 years ago. Rattly boots are crap! Cheers, Jason

_________________ {DESCRIPTION} - {DESCRIPTION}, {DESCRIPTION}, {DESCRIPTION}, {DESCRIPTION} and more! |

|||

| Top | |

|||

| B Bear |

|

|||

|

{USERNAME} wrote: Nice work on the turbo install, very neat job you're doing. Get a Fairmont boot lid carpet and that sound deadener job will come up mint. I did the same thing to my EF about 7 years ago. Rattly boots are crap! Cheers, Jason Cheers Jason Trying to keep the install as neat as possible, my old man has done some great work ! Can't wait to start it up and just hear it go for the first time. Yeah I added the carpet to the boot lid, wasn't very nice looking at all that shiny sheet when it was open |

|||

| Top | |

|||

| B Bear |

|

|||

|

Ok so with most of the parts connected up we cranked it over... It's only coming straight of the dump pipe and getting the exhaust stuff sorted out on Wednesday.

Sounds like a tractor !! {DESCRIPTION} |

|||

| Top | |

|||

| B Bear |

|

|||

|

Also decided on getting another fpr, with the one running now I'm not sure how well it will hold up.

Got a second hand Turbosmart FPR800 |

|||

| Top | |

|||

| Who is online |

|---|

Users browsing this forum: No registered users and 71 guests |