|

| B Bear |

|

|||

|

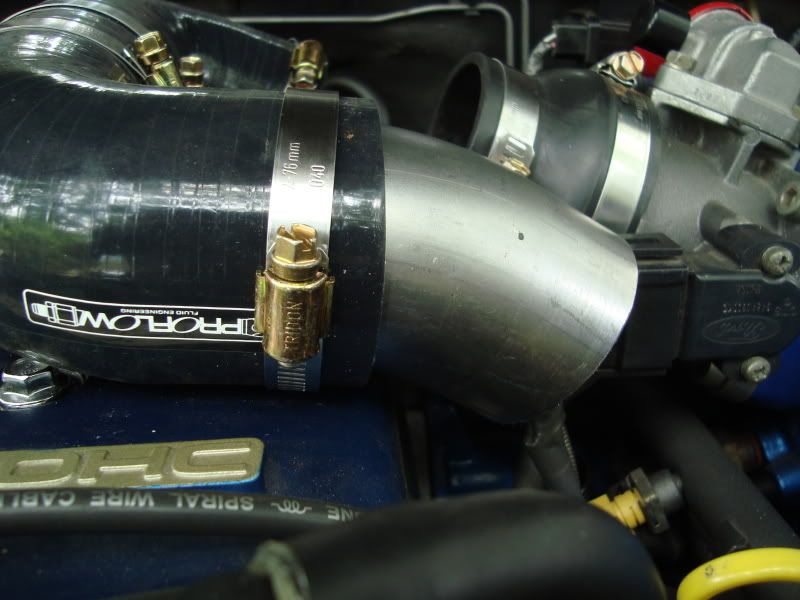

Mock pipe from the cooler to TB and Turbo is now done ! Going to take the pipe down the exhaust shop tomorrow and have them make up all the required pipe. Tried to keep the bends simple with 90 and 45 degree bends.

What it looks like in the car...     Also painted the dump pipe as I love painting something   Close up of how the waste gate pipe was created and fitted.  Might put it back on the car to heat it up and let it burn in, then wrap the top up in the heat shielding. |

|||

| Top | |

|||

| B Bear |

|

|||

|

Took the pvc pipe down to the exhaust shop today to get it all made up, should be done by Monday. Also picked up some metallic black paint to paint the pipe once it's done.

|

|||

| Top | |

|||

| B Bear |

|

|||

|

Got the intercooler pipe back today. Had it press bent in steel, after talking with Ron we decided to go with this as it was only $165 for the steel and the work.

Will paint it up tomorrow with some shiny black/grey paint. |

|||

| Top | |

|||

| B Bear |

|

|||

|

The silicon joiners to the TB sat a bit too high and were forced down by the bonnet when closed. So to over come this we replaced the straight bit of pipe with a 15° bend.

Also changed the position of the barb connector for the line back to the wastegate.

|

|||

| Top | |

|||

| B Bear |

|

|||

|

Over the weekend got a new radiator bottle, was sick of the dirty old looking one !

Also decided to get some different spark plugs... Ended up with some NGK ones that had a better heat range for the turbo setup. Actually checked out the ones Troyman suggested but they didn't have any at the shop. One of the guys there runs them in his BA turbo and says they do well. Originally gaped at 1.1 and brought it down to between .7 - .8  Also heat wrapped the dump pipe, this turned out really well and the length of wrap was plenty to do half the pipe which is what I wanted.  As we soaked the wrap in water, let it dry in the sun which made it shrink in more. Then put it back on the car and ran it for awhile to heat it up. Sure does a good job at keeping some of that heat in. |

|||

| Top | |

|||

| xr6_corbin |

|

|||

|

Good job on the heat wrapping, I did mine when the dump was on the car. Worst idea. Still worked but not as neat as your job. Plus I ended up using worm drive clamps instead of those ones you used as they were a bugger to get tight when you have no room to work with haha. What plugs are the NGK's ur using?

_________________ Just Falcon Around. |

|||

| Top | |

|||

| B Bear |

|

|||

|

Thanks mate, it definitely is a two person job whilst off the car. Soaking it in water made it a lot easier to work with as well. Oh and those clamps were a bit of a prick to work with, they are impossible to tighten by hand so just pulled them as hard as I could with pliers.

The spark plugs are: NGK (1095) BCPR7ES-11 the guy that recommended them said they are good because under boost the spark doesn't blow out. |

|||

| Top | |

|||

| xr6_corbin |

|

|||

|

Yeh it's so much easier when you soak it.

Oh ok the plugs I use are BPR6EY that are usually .8mm gap but I've gapped them down to .71mm with no probs so far. Runs 12psi

_________________ Just Falcon Around. |

|||

| Top | |

|||

| B Bear |

|

|||

|

Yeah those were the ones Troyman recommended but when we went to see if they had any none were there and the ones we got came in from their supplier 30 mins later.

I was surprised as how easy it started even though they are a colder plug, thought it would take more to kick the car over. |

|||

| Top | |

|||

| B Bear |

|

|||

|

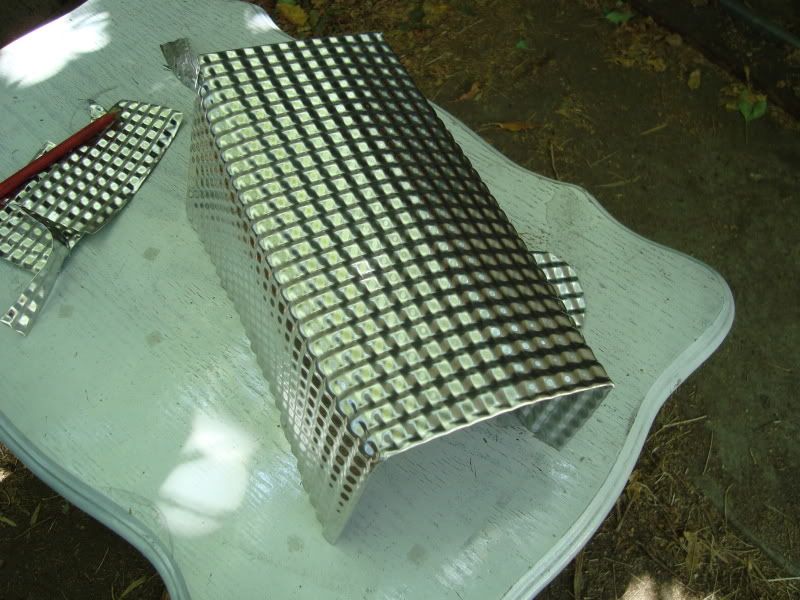

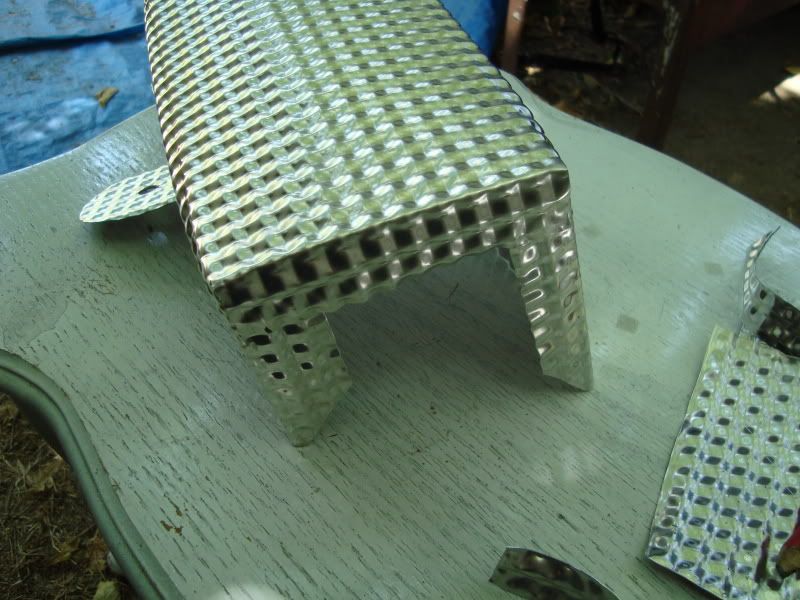

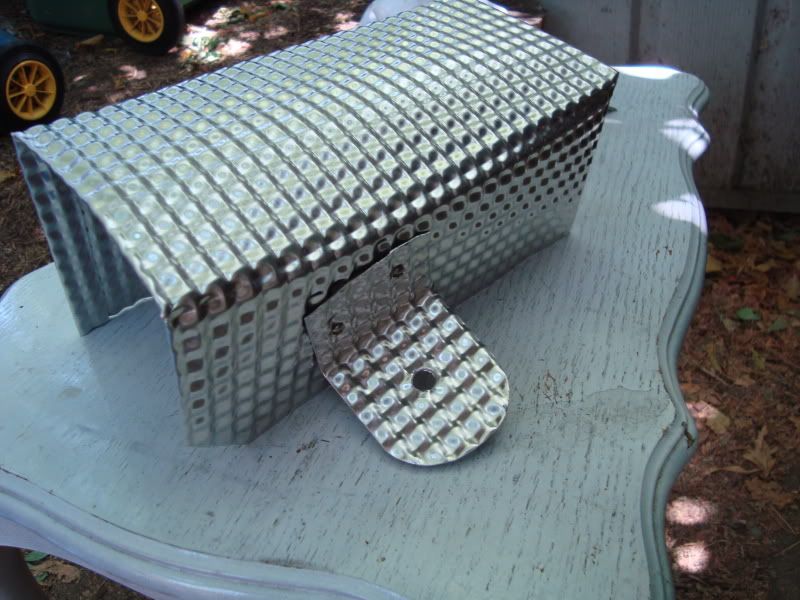

The dump pipe is back on the car and we had some heat shielding ready to be put on. It seems like the exhaust wrap is keeping temps down but want to keep as much heat away from the brake booster as possible.

Some crafty work by dad...

|

|||

| Top | |

|||

| B Bear |

|

|||

|

Intercooler pipe is all painted and installed back in...Also made a bracket for the front pipe as every so often it would sag or shudder around. This way it's held in more firmly but can still move if needed.

Covered up the throttle cable with heat tubing, sadly it doesn't fit the pipe at the back leading off the brake booster. So might invest in some more if there is still a lot of heat there.  Also got the boost tee installed, fits nicely near the turbo and can be adjusted easily. Won't hook it up until we get the tune done on the car.

|

|||

| Top | |

|||

| xr6_corbin |

|

|||

|

So what's the eta on tune for this thing? Looks like its almost done!

_________________ Just Falcon Around. |

|||

| Top | |

|||

| B Bear |

|

|||

|

I'm chomping at the bit to get it tuned, pay day next week and need to book in with the tuner so I am pushing within the next 2 weeks.

Nothing else to really do but put the catch can in, connect boost tee and put in boost gauge. Although might just loosely fit the gauge for the minute. |

|||

| Top | |

|||

| cwhitz |

|

||

|

if your looking for a good tuner i highly recommend errol from EFI dynamics in lilydale.

tunes the J3 and pretty much anything else. Straight advice, no B.S

_________________ {DESCRIPTION} |

||

| Top | |

||

| xr6_corbin |

|

|||

|

Why don't you hook up the boost tee now. Just wind it all the way down and it will run gate pressure. It's not like your going to be boosting it until its tuned anyway.

_________________ Just Falcon Around. |

|||

| Top | |

|||

| Who is online |

|---|

Users browsing this forum: No registered users and 52 guests |