|

| GrannyFalcon82 |

|

|||

|

Power steering hose update - Enzed recommendation

The two hoses were taken into Fyshwick Enzed, to hopefully be cut and crimped together. Well unfortunately for me, that wasn't simply the case. The great staff at Enzed listened to the story behind needing such an odd thing crimped, after them explaining why it can't simply be crimped together I understood why others here on Fordmods took a similar path. If the hoses are picked up and moved around, metal can be felt within the rubber. Iirc this is referred to as the restrictor, aiding with the responsiveness of said power steering. After Enzed had a look under the bonnet at what needed to be done I was told the hose being incredibly short was a serious issue. So the plan was to take all of the rubber off and have new crimps installed on either end, for the mean time the hose length is excessive. This is so once the engine goes in and all components are being connected, we can accurately determine the length needed by false fitting the hose, and marking where it needs to be cut / crimped, thus eliminating any fitment issues. A big thanks to Enzed for the physical and financial help they have given thus far. A shield will be made up to fit around the hose.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| fezlane |

|

|||

Age: 58 Posts: 434 Joined: 18th Jul 2009 Ride: NL FAIRLANE BA TURBO POWERED Location: ballarat |

Just don't plug solenoid in wont hurt for awhile.

|

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

Wiring update - Dash water temp sender wire adapter, fuel pump relay wire and alternator charge adapter

The alternator on the EA used the injector / coil type connector, for the charge voltage found in the cluster. This meant it would not simply connect up to the BA alternator and an adapter of sorts had to be made up. Thankfully i have around 12 spare fuel injectors to butcher, so one was sacrificed... with an angle grinder. Being careful not to take too much meat away from the connector, i proceeded to De-attach it from the injector body. Once off, there's then two flat copper surfaces to solder onto. A bit of a pain, yes however it is do - able, and it seems rather strong. I then soldered the BA alternator plug up to said EA loom connector. This means " plug and play " and no original loom has to be chopped ( This is very important if an engine revert is necessary in a short period of time )   Now the water temp sender on the EA is very strange... in fact i do wonder what was going through fords mind at the time. A smooth cylindrical connector mating up to what seems to be a small bit of threaded rod... This meant finding something that will fit into the EA loom side, that's easy to solder and looks neat. After experimenting with a tiny bolt, which wasn't fun by any means to solder onto, i scrapped that idea and thought about the inner of a " butt crimp connector ". In the kit i bought a while back, I had received two different sizes, one being large i removed the metal part. Didn't fit right being just a tad smaller than the diameter of the EA loom connector however it's split down the middle... After a bit of prying and soldering a wire onto it, i have something that will fit nice and snug. On the other end of the wire i soldered on a spare female connector to attach to the temp sender tab.   The fuel pump relay wire was a must, I did not like the idea of tapping into the loom as this meant destruction. After locating an EB XR8 wrecking, i had chopped off an entire fuel pump relay. He insisted that i not pay due to it being such a small part ( Cheers mate ). After sparking conversion with this guy, it turns out he has a turbo BA donk in an EF / EL. Allowing me the opportunity to have a look, we talked about the K frame being notched out to fit the engine and what engineers pick on in terms of modifications. The guy has a great interest in the later E series, however not so much the box cars  I've also added in the connections needed for the Tacho module once i purchase / install it. Thanks to Johnny for supplying me with a picture referring to necessary inputs. The IGNSNS wire is going to be supplying the 12V ignition feed, the module will be grounded to the body. The negative crank position sensor wire was also tapped into, also going through a connector to make install easier. The output for the dash is the same four pin connector in which i get the ignition feed and starter motor feed from.  I'll have to pop into the exhaust shop and think up some ideas about spacing the cat converter ( Needs to be a removable spacer, not a permanent piece ) Once the BA engine block is flushed of all the nasty stuff that lives in there, and the new K - frame bushes are installed i can begin planning the engine install.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

{USERNAME} wrote: Hi Bayden,how's the EA coming along,am just trying to work out the purge solenoid/canister and am thinking the best way to do it would be to use the BA solenoid with the XG canister,do you know if we're able to turn the purge solenoid off completely and block everything off (just temporary), have to do same thing with A/C till I get back and sort it all out-hoses made up etc, cheers, Johnny. Hey Johnny, The canister purge solenoid can be disabled in VCM editor, I'm unsure what the negative effects of doing this are. The solenoid is just a gateway between a vacuum hose, an electronic controlled valve. All you have to do is remove the XG one and slip the BA one in there. Or you can just wire up the XG solenoid instead. There's no need to mess around with the canister itself. My AC lines are going to stay disconnected for the time being. Eventually I'll have to get some hoses adapted, but i'd rather everything in the car that way i can't get the measurements wrong.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

Conversion complete

Well, the time has come... After installing new bushes in the K - frame and gathering a few bits and pieces, it was time to proceed with the DOHC heart surgery. Gladly, the surgery went very well... Video is here : https://www.youtube.com/watch?v=9rsgQzl ... CCU4inv52A Day one - Removed engine in 5 hours Old K - Frame out New K - Frame in Day two - Spigot bearing install Flywheel / clutch install T5 install with AU bellhousing and BA starter motor Wiring loom installed with throttle loom going through firewall Engine install Airbox assembly ect... General attaching of things Day three - Sorting out coolant hoses Installing wiring bits and pieces. Throttle pedal install Battery, thermo fan wiring ect... Power steering line install Done - driveable The cat converter has been pulled forward quite alot, this is temporary until an exhaust shop can mock something up. The exhaust leak at the cat / headers leads to a lot of head turning, so until it's fixed up it must be driven like a granny. Needless to say, it has alot more torque than the E series and I've yet to explore the powerband. Luckily for you guys, there will be POV footage of some driving with the new Barra. A Big thanks to my brother John for giving a helping hand during the engine transplant, makes time go by a heck of a lot quicker.       And yes, the bonnet clears This isn't by any means, the last post. So expect more in the future... If there's any information anyone needs regarding the conversion, don't hesitate to PM me and I'll try my best to help you out... If I, a 16 - 17 year old can complete this conversion mostly by myself in terms of funds / actual modding, anyone in the correct mindset can. Cheers.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| crossroads |

|

|||

|

Top stuff. You have done some awesome work there.

If you dont mind me asking.how much has the total conversion set you back at this point?

_________________ the road to hell is paved with good intentions. |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

{USERNAME} wrote: Top stuff. You have done some awesome work there. If you dont mind me asking.how much has the total conversion set you back at this point? Cheers mate, The conversion has set me back around $1800 - $2000... $2000 is a realistic base line figure for these conversions. Knowing people and having a half cut will bring the cost down considerably. Also note I had been selling parts off of the BA i bought ( Around $1500 worth ) So the conversion mostly paid for itself in my case.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| johnnyeHCF |

|

|||

|

Hey Bayden, awsome stuff dude-sounds good-a bit loud but good, have you driven it yet?, getting mine ready for a test drive- either today or tomorrow (depends on how hot it gets today),you get any DTC'S pop up (besides a/c)?, cheers, Johnny.

_________________ XG DOHC-BARRA 182/Turbo kit/20% Underdrive and BA 4-SPEED + Tiptronic shifter |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

{USERNAME} wrote: Hey Bayden, awsome stuff dude-sounds good-a bit loud but good, have you driven it yet?, getting mine ready for a test drive- either today or tomorrow (depends on how hot it gets today),you get any DTC'S pop up (besides a/c)?, cheers, Johnny. I drove it home right after the conversion was finished. The exhaust and cat are currently pulled up to the manifold, so there's a leak between the cat and manifold at this point in time, thus creating a bogan - like sound. It also affects the throttle response and running of the engine due to the leak being right underneath the 02 sensor... I've disabled the AC in VCM editor, so no codes there. The only codes i get is CAN bus error and a restrain code... which i believe is to do with seatbelts / airbag? I'm unsure. Other than that, everything seems to be fine. No oil leaks and no water leaks, the water temp sender has been replaced with a brand new $15 sender, so the temp gauge now works as per normal.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

Limp mode issues update 1

So the exhaust has been fixed up, the car sounds great now. When exploring the rev range i found that every now and then the engine would go into some kind of rpm guard mode, i wouldn't be able to exceed 3000rpm. This can be corrected by switching the car off and then back on however the same issue will arise in minutes. ( note that the speedo sender is wired in, however it doesn't seem to be reading it in the real time gauges. ) I've also noticed the lack of high end power. The bottom end is very strong, it pulls like a tractor however once i begin to explore the rev range, it hesitates and doesn't climb as expected. After a good run i've gone and checked the DTC's, and this is the list i have ended up with. P0325 - knock sensor 1 circuit bank 1 p0340 - camshaft position sensor A circuit bank 1 or single sensor p0500 - vehicle speed sensor A p1340 - camshaft position sensor b circuit p1380 - camshaft position actuator circuit bank 1 p1385 - camshaft position actuator circuit bank 2 p1565 - speed control command switch out of range high Well then... I guess the work begins!

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| twase |

|

|||

|

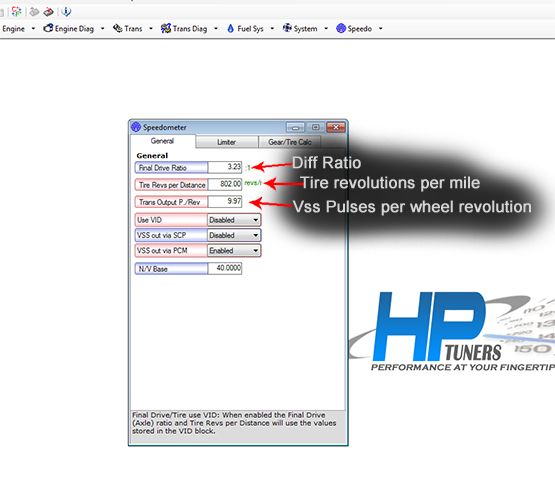

Speedo input is the key here, the Ecu needs a speed input, it needs to be setup for non abs, also the pulse per mile setting might also be critical here.

_________________ BF Fairmont Ghia Series II update. |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

PCM Reading EA VSS?

Well I found out why I wasn't able to log my speed. The BA PCM connector pin holder had broken in slot B07 unfortunately, this meant pulling the loose pin through the connector and soldering onto the end of it, preventing it from pulling back through. That wire runs from the EA vss loom ( 998 Red ), to the BA PCM connector ( Pin B07 ). The speed seems to be logging just fine, however adjustment is needed as I'm most definitely not doing 114 Km/h in an 80 Km/h zone. Some calibration and long driving will be needed to determine whether or not it has fixed the limp mode, ultimately bypassing a trip to Ford. The cams also seem to be stuck at -10 deg according to the data log, might explain the lack of top end power. Hopefully it's a wiring issue and doesn't require pulling the rocker cover

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| johnnyeHCF |

|

|||

|

Hi Bayden, what needs to be changed in VCM editor for the speedo input from the transmission, got me buggered, cheers, Johnny.

You do not have the required permissions to view the files attached to this post.

_________________ XG DOHC-BARRA 182/Turbo kit/20% Underdrive and BA 4-SPEED + Tiptronic shifter |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

{USERNAME} wrote: Hi Bayden, what needs to be changed in VCM editor for the speedo input from the transmission, got me buggered, cheers, Johnny. To my understanding, these are the parameters needing adjustment.  Final drive ratio ( diff ) : Use your diff ratio here Tire Revs per distance : refer to link below Trans output P/Rev : Unsure as of yet Use VID : Disabled VSS out via SCP : Disabled VSS out via PCM : Enabled N/V Base : Left alone I'm unsure if the software is referring to the factory VID block containing all of the information, or the adjustable parameters above. None the less, this will be a trial and error process for me. Use this to determine tire revs per distance ( Unsure if this parameter is used if the VID option is disabled ) http://www.tyresizecalculator.com/tyre- ... dimensions I Had no clue about the VSS pulses per mile, a quick google search didn't find much but an UN-quotable figure of 8000 pulses per mile. I had just used this quick calculation to determine the pulse per mile : 8000 / 802 . Giving me 9.97 pulses per revolution. I've yet to find out if this will work as my speedo transducer is having a hissy fit.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| johnnyeHCF |

|

|||

|

Hey dude, thanks for the help with the speedo-settings on HP seem good but the wire to B07 is the white wire from the speedo sender, can't believe it is changing gears just need to make a few adjustments-even the tiptronic is working, cheers, Johnny.

_________________ XG DOHC-BARRA 182/Turbo kit/20% Underdrive and BA 4-SPEED + Tiptronic shifter |

|||

| Top | |

|||

| Who is online |

|---|

Users browsing this forum: No registered users and 71 guests |