|

| johnnyeHCF |

|

|||

|

Hi mate, I got my tacho module of muzza here on fordmods (awesome bit of kit), cheers Johnny.

_________________ XG DOHC-BARRA 182/Turbo kit/20% Underdrive and BA 4-SPEED + Tiptronic shifter |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

Wiring update 9 - PCM and Relays sounding functional

While thinking of my next move, i decided i'd go ahead and test out the PCM power and grounds. Now this was pretty nerve racking, weeks worth of work on the wiring, making sure that all the wires go in the right spot. I used an SCA jumper pack as the battery, hooked up both positive and negative terminals up to the jumper pack clamps, wired in a button as the ignition signal straight from the B+. As I stood there in anticipation of a fire to occur, to my surprise nothing was burning Note that power still runs to the PCM while the ignition is off, these connections are : PCM Pin B40 - Keep alive power ( Constant 12v positive battery connection ) I believe Without "Keep alive power", there will be issues where the PCM will need to re learn every time the car is started. Like what happens when the battery is disconnected for a period of time. Now that I'm confident with the PCM wiring, it's time to continue.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon Last edited by GrannyFalcon82 on Thu Jan 01, 2015 6:07 pm, edited 2 times in total. |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

Engine mounts update 1 - Lowered by 11mm

When putting a Barra into the E series, the bonnet will collide with the rocker cover if the engine mounts are left alone. People have compensated by either lowering the engine mounts or cutting the bonnet bracing ( I've read up on spacing the K frame down, not sure if it's been done successfully however ) I Chose to lower the engine mounts, that way the motor will drop right in without having to ruin the bonnet. The bolt holes are an 11mm diameter, and to " Drop the engine mount " I Simply drilled 11mm holes right beneath the existing holes ( I did NOT slot the holes, this way the engine cannot lift under it's own torque roll. However i may end up finding some rod the same diameter, and plug the old mounting points. After i've modded the K - frame to fit the Barra double chin, i'll test fit the engine onto the K frame out of the car, to make sure everything lines up / is straight. Also concerned about rear sump / cross-member clearance, but if any issue arises it shall be dealt with.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| Mad2 |

|

|||

|

lokkin goood!

|

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

General update 1 - Firewall cracked due to heavy clutch

G'day all, Yes I'm still alive, I've had priorities as of late to take care of, progress will indeed continue with the barra donk conversion! For quite some time i've been battling the clutch's engagement point, i'd adjust it one day and the next it'd engage way down at the floor. After scratching my head for some time i decided to go and check the firewall, as the falcons are notorious for cracked firewalls... The moment i saw a 50cent sized crack, my heart sank. After using it for a couple of more weeks, i ripped the booster off, cut the insulation off and discovered this.   Luckily for the average DIY'er, there's a very simple fix... Using 5mm Thick plate ( Overkill, yes ) I could make a really big " Washer " for the clutch cable, it has to be large to spread the load over a wide surface area.  The falcon firewall has a ridge running downwards, to the right of the cracked piece. I've shaped the flat steel to fit snug in there ( Trying to cover as much area as possible ) Where the cable shall run through, i've drilled an angled 13mm hole into the steel plate, similar to that of the original angle. Using the same size piece of tubing with a smaller inside diameter ( It's 2mm thick ) That also being on the exact same angle, tac welded all the way around. Clearly in the photo i didn't have much fun trying to stick weld 2mm thick steel with damp 2.5mm 6013 rods. The weld looks absolutely atrocious, at some point i'll try again with a mig or tig, but for now she'll be right. Mounting this plate to the firewall is an easy task with self tapping screws ( It's pointless using bolts, as the plate will be PULLED towards the firewall )  Finished product, so far no issues with cracking, clutch feels 100% better too. The insulation will be re attached when the engine is out ( Purely cosmetic... )

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| Mad2 |

|

|||

|

{USERNAME} wrote: General update 1 - Firewall cracked due to heavy clutch G'day all, Yes I'm still alive, I've had priorities as of late to take care of, progress will indeed continue with the barra donk conversion! For quite some time i've been battling the clutch's engagement point, i'd adjust it one day and the next it'd engage way down at the floor. After scratching my head for some time i decided to go and check the firewall, as the falcons are notorious for cracked firewalls... The moment i saw a 50cent sized crack, my heart sank. After using it for a couple of more weeks, i ripped the booster off, cut the insulation off and discovered this.   Luckily for the average DIY'er, there's a very simple fix... Using 5mm Thick plate ( Overkill, yes ) I could make a really big " Washer " for the clutch cable, it has to be large to spread the load over a wide surface area.  The falcon firewall has a ridge running downwards, to the right of the cracked piece. I've shaped the flat steel to fit snug in there ( Trying to cover as much area as possible ) Where the cable shall run through, i've drilled an angled 13mm hole into the steel plate, similar to that of the original angle. Using the same size piece of tubing with a smaller inside diameter ( It's 2mm thick ) That also being on the exact same angle, tac welded all the way around. Clearly in the photo i didn't have much fun trying to stick weld 2mm thick steel with damp 2.5mm 6013 rods. The weld looks absolutely atrocious, at some point i'll try again with a mig or tig, but for now she'll be right. Mounting this plate to the firewall is an easy task with self tapping screws ( It's pointless using bolts, as the plate will be PULLED towards the firewall )  Finished product, so far no issues with cracking, clutch feels 100% better too. The insulation will be re attached when the engine is out ( Purely cosmetic... )  most of us have had that problem re firewall [have repaired that re xgirlfriend using steel plate & pop rivets] and will be making sure it dont happen with me wagoooon eitha .... have just bought a BA/BF manual pedal setup too i wouldn't worry about the insulation ....... mine was removed before i bought it .. glad it was too!! |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

K - Frame Update 1 - Off to the shop it goes

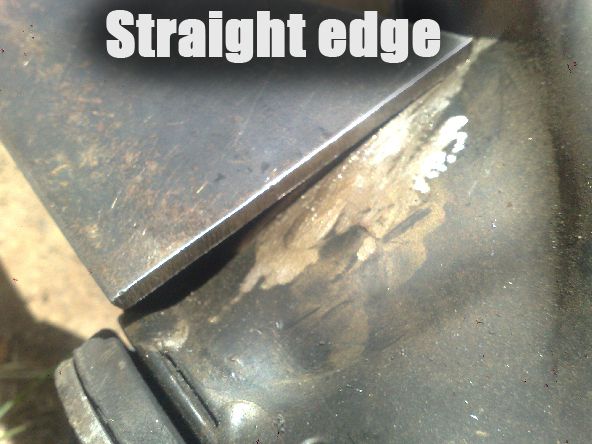

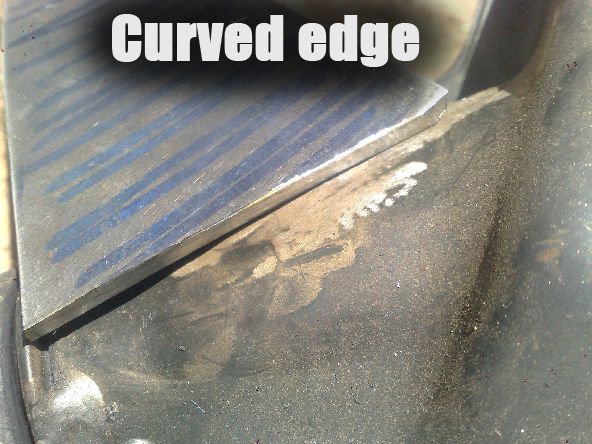

G'day everyone, sorry for the slow progress... The K - Frame as we all know, has to be modded as the sump just hits the damn square tubing. I've dropped the tacked together K frame at the local exhaust shop for some structural welds, i'd much prefer someone with more welding experience and better machinery to take up the task. I've bought some solid bar ( yes, solid bar ) and cut it to 560mm long, tac welded that as far forward as i can get it. The aim is to make this mod look somewhat similar to factory, for obvious reasons...  The side brackets are 1/4" steel plate, overkill? maybe. After tracing the original brackets and cutting up some new ones, i discovered the joy i would have getting them flush to the rounded surface just above the bushes. A Curved edge was necessary along with an angled edge to sit as flush as possible to the rounded surface ( This way the welder has more metal to work with ) Half of the space will just be filled in so it doesn't look odd.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

K - Frame update 2 - Welding complete

Went down to the exhaust shop around lunch time and picked up the K - frame, which had been welded after being prepared properly on Friday. I'm very stoked with the results as there is some nice strong welds in there. Where the rounded surface starts to dip down and flare back up ( Front of the bush ) is where there's no structural weld, purely filled in for cosmetic reasons, good on the welder. The K - frame looks factory thankfully, even has the protruding edge at the front. Hmmm, to paint black or factory color... this is the question.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

PCM Bracket update 1 - Bracket cut and screwed together.

The PCM bracket sits on the passenger strut tower, it will bolt straight up however the bonnet will just barely shut properly. As we can see here I've chopped the bracket, lowered and screwed it back together... Also using a dremel I've cut away protruding edges ect... Once i get to the stage of painting everything, this will get a touch up. The bonnet shuts absolutely fine and that's without the bracket being bolted in. The only downside is that I've had to remove the washer bottle as that got in the way.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

Water temp sender update 1 - Ideas

One thing is for sure, i'd like to know the temp of the coolant after this engine swap, and luckily for me that's easy done. The EA dash only requires the small temp sender to have resistance to ground. I believe this isn't the case when using an EL ECU. A quick trip to enzed and discussed what i needed, the brass elbow was the best choice as it could be drilled and tapped rather easily. I'll be using an ED temp sender as i cannot stand the current EA design ( Some kind of threaded rod ) That will be screwed into the brass elbow which sits before the heater tap, it will need to be grounded around the threads, i've achieved this by using a large crimp terminal and slightly drilled it out to slide over the threads. The wire that connects to the spade terminal will run to the EA loom and plug in with something similar to a threaded bolt. I've tested this with some boiling water and it works as expected, the wiring will have to be prettied up with some corrugated tubing / tape. But it will be something along the lines of " plug n play ". The elbow itself is going to be a tad harder to deal with as it's a 90 degree bend. I've sorted this by using a piece of hosing that's also got a 90 degree bend. Before engine installation i'll be buying all brand new hosing ( Expensive, but worth it in the long run ).    This isn't the design i'll be using, it will need a durable connection.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

At this stage I'm in need of an AU T5 bellhousing. If anyone has one laying around PM me for pricing.

Cheers

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| Mad2 |

|

|||

|

{USERNAME} wrote: At this stage I'm in need of an AU T5 bellhousing. If anyone has one laying around PM me for pricing. Cheers NO you can't have mine |

|||

| Top | |

|||

| macxr8 |

|

||

Age: 56 Posts: 451 Joined: 3rd Jan 2005 Ride: AU XR6 with BF Turbo engine Location: Sydney |

{USERNAME} wrote: At this stage I'm in need of an AU T5 bellhousing. If anyone has one laying around PM me for pricing. Cheers I have one, but it comes with a box and tailshaft if your interseted

_________________ RIP |

||

| Top | |

||

| GrannyFalcon82 |

|

|||

|

{USERNAME} wrote: {USERNAME} wrote: At this stage I'm in need of an AU T5 bellhousing. If anyone has one laying around PM me for pricing. Cheers I have one, but it comes with a box and tailshaft if your interseted I would if the budget allowed for it mate

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| johnnyeHCF |

|

|||

|

There's one on ebay atm $150 +$29 postage item no:231383583025, if your lucky you may find one cheaper-but there's not many around unlike the E-series.

_________________ XG DOHC-BARRA 182/Turbo kit/20% Underdrive and BA 4-SPEED + Tiptronic shifter |

|||

| Top | |

|||

| Who is online |

|---|

Users browsing this forum: No registered users and 196 guests |