|

| GrannyFalcon82 |

|

|||

|

AC Compressor clutch switch update 1 - Design sorted

G'day everyone, I've thought this over for a while trying to think of a simple but effective design to make the BA compressor work with the EA switch. The EA Falcon AC compressor has one signal wire coming out of the body loom, which attaches to the compressor via male wire. The EA compressor has a ground on itself along with a cutout switch, the BA compressor will have no sort of safety as it will be a simple on / off operation. The BA Falcon AC compressor has a plug right up near the pulley, two male pins. Most electrical connectors on the BA seem to be unique, unfortunately for me this meant chopping the connector from the engine loom ( It tucks back away in the corrugated tubing ). I crimped and soldered a male ring terminal onto the thinner black wire which would be sandwiched in between the compressor / mounting bolt. That will be the ground for said solenoid. The longer wire as seen in the photo, simply plugs into the EA body loom ( It's a single blue, female connector ) That's the positive voltage sent by the switch / relay. I've also slid on some plastic sleeves from the wire itself and from an old 02 sensor, this will provide protection to the wires along with cosmetic reasons. Also yes that heater pipe bracket is in the way of the AC piping, time to think of something else.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

( Post deleted )

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon Last edited by GrannyFalcon82 on Fri Dec 05, 2014 6:49 pm, edited 1 time in total. |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

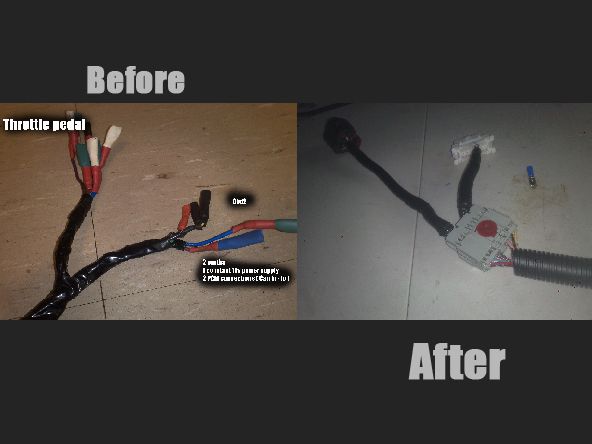

Wiring update 10 - OBD2 / Throttle pedal mess cleaned up.

Today i decided to get out the soldering iron and fix up a huge mess i had left in the wiring loom. The connections between the loom and OBD2 port / Throttle pedal were nothing but flimsy and unsightly. The new design consists of one small connector, however it has 12 available pin slots ( Re - pinned to 11 ) The accessories are soldered to the male side of the connector ( larger side ) The wiring loom side is connected to the female side ( Much smaller ) I cannot remember how large the throttle cable hole in the firewall is, so for now i'll hope that i can just turn the female connector sideways and wiggle it through, otherwise i'll just have to remove the pins ( Really easy with the SMALL screw drivers ) pass it through, and slide the pins back in.   Other things I've done to the wiring loom, The PCM connector for this custom loom, was rather thick and that was due to all of the unused pins. Instead of chopping the wires back further, I simply removed the red cover inside the connector by GENTLY prying with a small screw driver, it just slides off. The pins were a bit of a pain to remove as they are damn small and held in by tiny clips. Oil pressure sender is currently wired into the engine harness and crosses over to the custom wiring loom via single connector. Fuel pump relay wire is wired into the PCM, awaiting appropriate relay pin to replace the EA ground with. Purge canister solenoid is now wired up to the PCM. Things I may do, Connectors near the PCM are rather thick, I'm considering removing the crimps from one connector ( It has a lot of connections ) and replacing it all with soldered connections to reduce thickness. This will enable me to use the same size corrugated tubing for everything, I believe it's 20mm in diameter. The fuse panel / relay box currently consist of flimsy crimp connections with heat shrink as an insulator / sleeve. I will experiment with some spare relays, however I'd like to create a simple and DURABLE setup where one electrical connector is needed for each side, instead of having a huge mess and waiting for a connector to vibrate loose while driving. EDIT : Sorry for the double post, for some odd reason the larger photo above had cut off text and prevent me from editing the above post.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

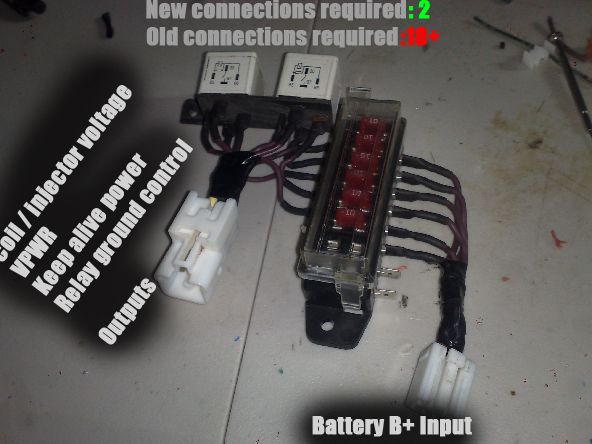

Wiring update 11 : Fuse panel / Relay wiring mess gone!

G'day everyone, as the previous post has demonstrated, the loom is getting a little bit of modification to iron out the kinks. ( Soldered, not crimped ) I've re designed the relay / fuse panel section to become a lot simpler / durable, whether or not the connectors will handle the amps drawn I'm unsure ( I will document any issues ) The previous design consisted of independent loose wires requiring single connections ( This also meant figuring out, each time, where to place everything ) That nightmare is over thankfully as the new design consists of two required connections, inputs and outputs. The input connector is a 6 pin connector only requiring 5 pins ( 6th pin in there in case I need a reason to use it ) Output connector consists of four pins, Coil / injector voltage ( concerned about amperage drawn ), Vpwr (PCM Pin B34, B36), Keep alive power and the relay's ground control (The PCM controls the ground of the relays, this activates them, but the PCM needs Keep alive power in order to operate ) The grounding wires form into one wire before the connector. This new design also eliminates the chance of wires vibrating loose during engine operation.     I've just tested this out with a car battery, everything seems to be functioning properly, very quiet sound from the PCM, correct voltages around the loom ( OBD, Throttle, 02, Canister purge S, Runner control S ect...) Once I'm able to sell this gearbox, I'll purchase the hardware / software from HP tuners and tinker around with the PCM.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

General update

Well guess what arrived yesterday, indeed! That expensive a** $200 bellhousing i had ordered actually arrived earlier than expected. He works fast, that's obvious because there was clearly no time for a quick pressure wash! Here it is, in it's plastic womb and came with the clutch fork, which surprisingly doesn't have much wear on the block it sits on.  As we can see here the AU t5 bellhousing is rather dirty, as expected for any falcon. I hate dealing with, not so much dirty but " cruddy " items as it makes a darn big mess and looks unsightly.  A quick pressure wash with half a can of dub dee 40 does the trick.  The clutch fork also now looks brand new. The housing has been bolted up to the Barra and everything seems to line up absolutely perfectly, happy days. The sump however will need to be drilled out, I'm torn between a hole saw or a large drill bit...  Also if anyone is interested in the BA front suspension setup, come and take it for $150 or pay for shipping. ( If interested, PM me )

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| johnnyeHCF |

|

|||

|

Hi mate,love your work-its coming together nicely, wanted to ask you about the temperature sensor and temp gauge sender-the gauge one is the small one? & the other one is the temperature sensor for the ecu-is the ecu one necessary if using the ba ecu or does it need the input to stop the E-series ecu from going into lhm,hope that makes some sort of sense

_________________ XG DOHC-BARRA 182/Turbo kit/20% Underdrive and BA 4-SPEED + Tiptronic shifter |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

{USERNAME} wrote: Hi mate,love your work-its coming together nicely, wanted to ask you about the temperature sensor and temp gauge sender-the gauge one is the small one? & the other one is the temperature sensor for the ecu-is the ecu one necessary if using the ba ecu or does it need the input to stop the E-series ecu from going into lhm,hope that makes some sort of sense G'day Johnny, What falcon do you own, if you're running an EA-EB-ED the dash temperature gauge is indeed the smaller single tab sender ( This works on ground resistance, the threads HAVE to be grounded ). If you own an EF / EL AFAIK they rely off of the two pin ECU sender, which is then connected to the cluster by some sort of data line. Good thing I own an EA There's no limp mode if the ecu doesn't even see a running engine. For the ECU to even function for necessary tasks such as AC wot cutout or fuel pump control, the computer will need a PiP signal. Without it, it's as useful as leaving key on engine off. My fuel pump will be controlled by the BA ECU ( It's only a relay grounding wire ) " Replace EA fuel pump relay ground ( 97, Brown / green stripe ) With BA PCM wire ( 926 ) " Cheers. Just thought I'd give everyone a heads up while I'm posting, the HP Tuners hardware has been ordered. I have no clue when it will get here, however I'm rather interested in tinkering around with it

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| johnnyeHCF |

|

|||

|

Hey mate (what's your name & can't call you Grannyfalcon), it's a XG was meant to be a manual with FG manifold, but decided to go with the auto and leave the other engine for something else, here's a pic of where I'm at, I've done opposite of you mechanical first then electrical to try and minimize wiring and use as much of the xg's components as possible-went in fairly good using xg engine mounts + because I used the xg extention housing on the ba auto I have speedo sender and trans cross member bolted up just like it was meant to be, now comes the fun part-Wiring

Cheers, Johnny. You do not have the required permissions to view the files attached to this post.

_________________ XG DOHC-BARRA 182/Turbo kit/20% Underdrive and BA 4-SPEED + Tiptronic shifter |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

{USERNAME} wrote: Hey mate (what's your name & can't call you Grannyfalcon), it's a XG was meant to be a manual with FG manifold, but decided to go with the auto and leave the other engine for something else, here's a pic of where I'm at, I've done opposite of you mechanical first then electrical to try and minimize wiring and use as much of the xg's components as possible-went in fairly good using xg engine mounts + because I used the xg extention housing on the ba auto I have speedo sender and trans cross member bolted up just like it was meant to be, now comes the fun part-Wiring Cheers, Johnny. Good point, I'd change my username if I were able to. ( Bayden ) Digging the blue mate. May I ask why you've taken the automatic route? My EA as it is now is rather responsive and once the Barra is in there, it's going to be a whole lot of fun! The XG's temp sender surely can't be far off of the EA design, as long as you've got it grounded there shouldn't be any issues. Wiring may seem difficult at first, once you understand it ( and take your time doing so, comprehend what's going where ) it will become a lot easier. The most annoying part for me was figuring out the wiring length for each item. An automatic pair of wire strippers, soldering iron and lots of heat-shrink make the job easy. If you haven't discovered this site yet, here's an excellent pin-out of the BA ECU. BA : http://www.fordforums.com.au/vbportal/v ... icleid=686 ( Look down at EEC-B, that's the body loom ) If you have any questions regarding wiring, give me a yell. BF : http://www.fordforums.com.au/vbportal/v ... icleid=687 I agree that the learning part is a good experience, this community has provided a lot of useful information and help, It's only right that I return the favor. Cheers

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| johnnyeHCF |

|

|||

|

Hi Bayden, yea I went the auto route mainly because of time restraints and the fact I would have to do some amazing Falcon juggling just to get the bastard out my shed + I had a full BA XR6 ute (auto) to play with,even got the tiptronic shifter in and still have the holes in the xg trans tunnel in case I need to reverse the conversion for any reason (I doubt it though) & your definitely right about giving back to the ford community, will be doing a build thread soon and cover some of the automatic side of these conversion's.

Cheers, Johnny.

_________________ XG DOHC-BARRA 182/Turbo kit/20% Underdrive and BA 4-SPEED + Tiptronic shifter |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

( Post removed by author )

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon Last edited by GrannyFalcon82 on Sat Dec 13, 2014 9:00 am, edited 1 time in total. |

|||

| Top | |

|||

| turbo_will |

|

||

|

Nice, what kind of dollars did it cost you to get the hp tuners setup?

|

||

| Top | |

||

| GrannyFalcon82 |

|

|||

|

{USERNAME} wrote: Nice, what kind of dollars did it cost you to get the hp tuners setup? The entire kit cost $923 including shipping If you're going with SCT expect to pay around $1200 " HP Tuners MPVI Pro - Ford - $895: http://www.vcmstore.com.au/index.php/vc ... -ford.html SCT - $795 hardware : http://www.ebay.com.au/itm/SCT-X3-FLASH ... 53ef0001bb ( This isn't for a ford, but it's the same price ) SCT - $395 tune file : http://www.ebay.com.au/itm/MailOrderTun ... 53e4b0bce7 View the price down below for FORD Stock Transplant Tune "

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

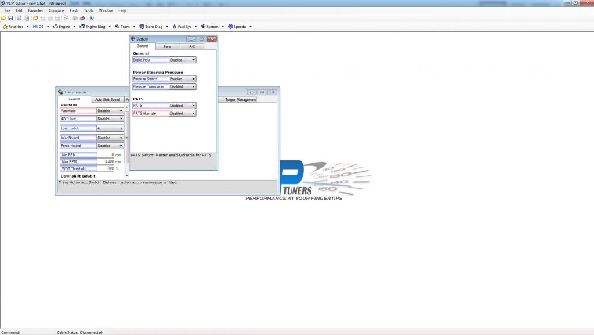

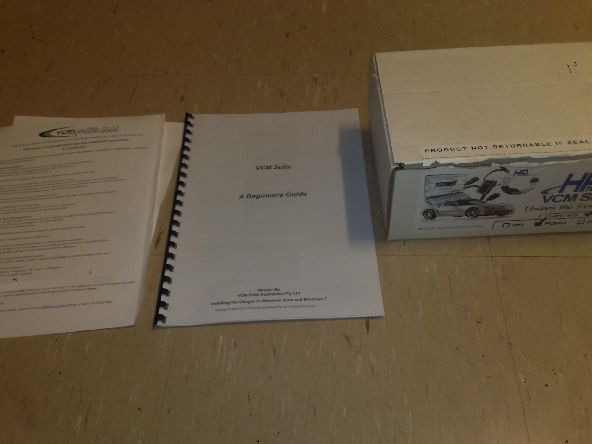

HP Tuners has arrived, installed and working!!

G'day everyone, sorry for the lack of update this week. On Tuesday I had received my HP Tuners MPVI Ford - Pro unit, that had been purchased on Sunday... Processed late monday, posted overnight (ASK FOR AUSPOST as Couriers please are no good in my experience, Auspost is also 1/2 the price... ) From Tuesday onwards I had trouble getting VCM suite to talk to the PCM, this however wasn't their fault as I had something wired incorrectly ( Will update that, shortly ) Once I got the box communicating with the PCM, It scanned all of the parameters / OS available. HP Tuners have made this program rather user friendly, and the PATS disable / Automatic disable + Manual gear ratios are not hard to find nor adjust. Well why didn't I just go with SCT... Well now I can use the laptop Paul Walker style in the falcon, i'll also be able to muck about with DTC's, Data logging and actual engine tuning. I Currently have 6 credits left ( 3 BA's / FG's ) No " Reverting back to stock " Needed. I Understand the SCT x3 can do the basics, however it's rather limited for my needs / wants, and I don't fancy looking at a tiny screen. Call me a hater if you wish, I prefer 100% DIY. Once the engine fires up, I'll be releasing a guide on what to do in the program... This is PATS disabled / Automatic transmission disabled  All of the hardware that comes with the kit  HP Tuners have included a guide to installing / tuning  The Interface A.K.A " The Box "  Sorry for double post once again, the larger photos seem to put everything out of proportion, once editing becomes available I'll remove previous post.

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| GrannyFalcon82 |

|

|||

|

I Can confirm the EEProm power supply had been wired incorrectly as i thought it was operated by a simple 12V current. Another look at the wiring schematics had me relieved, the EEProm power supply should be wired up to pin 13 of the OBD2 port. Everything works flawlessly now...

I've picked up the fuel tank in order to start the engine safely, not long until a video will appear

_________________ Rolling around with a Barra 182 - equipped 1988 EA falcon |

|||

| Top | |

|||

| Who is online |

|---|

Users browsing this forum: No registered users and 193 guests |