|

| D.J. |

|

||

|

Bwahahahahaha ......

|

||

| Top | |

||

| xcabbi |

|

||

|

Well I guess its time i provide you lot with an update of where I'm at incase you think I've had a nervous breakdown, scraped it and gone hiding in some cave with the mountain goats for the rest of my life.

The engineer has given me a few hoops to jump through with regards to clearances and over time I have been adressing these issues one by one. Sump clearances. Because I'm running hydraulic mounts the engineer specified a minimum thumb thickness clearance between the sump and any components such as steering arm, diff, etc so I needed to lift the engine up a tad. This is what I came up with. A 5mm shim cut out with a hole saw. Note the 2 small holes. One is for the pin on the top of the mount to pass through and the other is tapped and threaded for an M6 bolt to act as an extension as the pin is not tall enough with the shim in place.    And the extra clearance.

|

||

| Top | |

||

| xcabbi |

|

||

|

And now the body lift and trans tunnel clearance. This is going to be the biggest f**k since all those trial fitments of the motor to get the mounts in the right spot.

The Engineer initially wanted the body lift gone until he took a quick look at my trans tunnel clearance then he specified it to be reduced to 1" (formerly 2"). So like Matt I made myself a version of the werro engineering body lift blocks but mine were the Dapto edition, cut out of a bunnings chair leg (at least they are round). I found that with 1" body lift the trans tunnel on the passengers side was almost touching the bellhousing.  So we stepped it up to 1.5" and we didn't fare that much better.   After talking to the engineer he decided that I should now have a 40mm body lift and perform some surgery to the passengers side of the trans tunnel. A job I dread doing as its an engine and box out job. That's the plan for this week. Once this is done then Mr Dazfab can do his magic with the long awaited exhaust manifold. |

||

| Top | |

||

| xcabbi |

|

||

|

And now onto the topic of the legalities of body lifts themselves.

After seeing the following pics I think that some of you might agree with me that I think that poly blocks should be illegal like in QLD (about the only forward thinking thing in that state with regards to road worthiness). As it stands in NSW they are legal if steel crush tubes of a suitable wall thickness are fitted. At the time I didn't know this so I had ordered some ebay special poly blocks fitted. Even with crush tubes fitted I think the deformation would have been similar to the following pics. They have only been in the car for 2 years. I don't know how wide they balooned out to but their height was 53mm at the edges and probably about 48-49mm at the middle.   Not to mention the deterioration of them if they are located near any exhaust components.  This one was directly above the tailpipe and I was scratching bits of plastic off it with my fingernails. The good thing is my machinist got me in touch with a new steel supplier in the Illawarra (Bohler Uddeholm) and half a metre of 50mm Alloy round bar was only 50 bucks. All I have to do is part it off in 40mm pieces and drill a 12mm hole in each block. So far it works out to be a lot cheaper than the $350 snake racing want for their hilux/4runner alloy body lift kits. So that's about it for now. The spanners are turning, albeit very slowly. |

||

| Top | |

||

| low_ryda |

|

|||

|

hmm might have to look at my plastic blocks lol. Thanks for the pics.

_________________ Not to get technical, but according to chemistry alcohol is a solution. |

|||

| Top | |

|||

| D.J. |

|

||

|

Many years ago I did have the poly blocks also, and they deformed as well.

BTW they are legal in Qld provided they have a 6mm? wall crush tube, although personally I would not never use poly blocks again. Currently I have no body lift at all as I removed it prior to the engine swap. Can't remember the distance from bottom of front x-member to crank pully, but will get them for you if it would help. My engine is mounted with 2 deg. nose up in the car. |

||

| Top | |

||

| xcabbi |

|

||

|

Mines nose up too. My engine also sits higher up than yours because the Australian V8's had the trans brace factory fitted. IIRC the US spec HO's didn't. Also my bitsa of a sump requires that I lift the engine up as well. Once the body is sitting right then the light at the end of the tunnel will start to shine just that little bit brighter.

|

||

| Top | |

||

| xcabbi |

|

||

|

Well there is some good news and some bad news, potentially terminal depending on what the engineer has to say about it.

The good news is that the gearbox to trans tunnel clearance seemt to be sorted with the 45mm alloy blocks.  And now on to the bad news. The temporary wood blocks I had in there must have softened up from the rain because I have just realised that my left inner guard has started to tear away from the firewall.  Right now I'm just waiting on feedback from the engineer as to whether this crack signals a premature end to Project Fordrunner. Its only glued together from the factory so I am remaining hopeful. Funny thing is that is the only place on the whole body that there is any visible damage. Also all of the panel gaps seem to be just like the factory and there is no real difference between the right and left side. Are there any panel beaters that have had to repair anything similar or am I pretty much f**k? |

||

| Top | |

||

| Matt_jew |

|

||

|

There is nothing wrong with it.

The 4skinner is a full chassis vehicle. The inner guard is in no way a structural member of the vehicle. It is mearly for bolting the mudguard onto. You could chop it out , put tube work in to mount the guards and radiator support too and it would be fine. Dont even talk to the engineer. He will make headaches for you for no reason about this one. Just weld a strap or something in if your worried about it , otherwise just re-urethane it. Your panicking about nothing dude!!!!

_________________ {USERNAME} wrote: More people paid for a ride in a VT commodore then an AU Falcon so the VT is superior.

Based on that fact my Mum is the best around! |

||

| Top | |

||

| xcabbi |

|

||

|

Too late I fired off an email to the engineer as soon as I saw it. He just said to try and close the gap up, pump it with sikaflex and wait for 24 hours for it to cure.

Im just waiting on the engineer to get back to me on 45mm of lift and once that's finalised Daz can come over and do his magic with the exhaust manifold. |

||

| Top | |

||

| xcabbi |

|

||

|

We have some more progress.

After dragging it round the back under shelter I can now work on it rain hail or shine.

|

||

| Top | |

||

| xcabbi |

|

||

|

In order to make the 12mm bolts for the body fit I had to swap out the steel sleeves underneath cause they only have a 10mm bore.

|

||

| Top | |

||

| xcabbi |

|

||

|

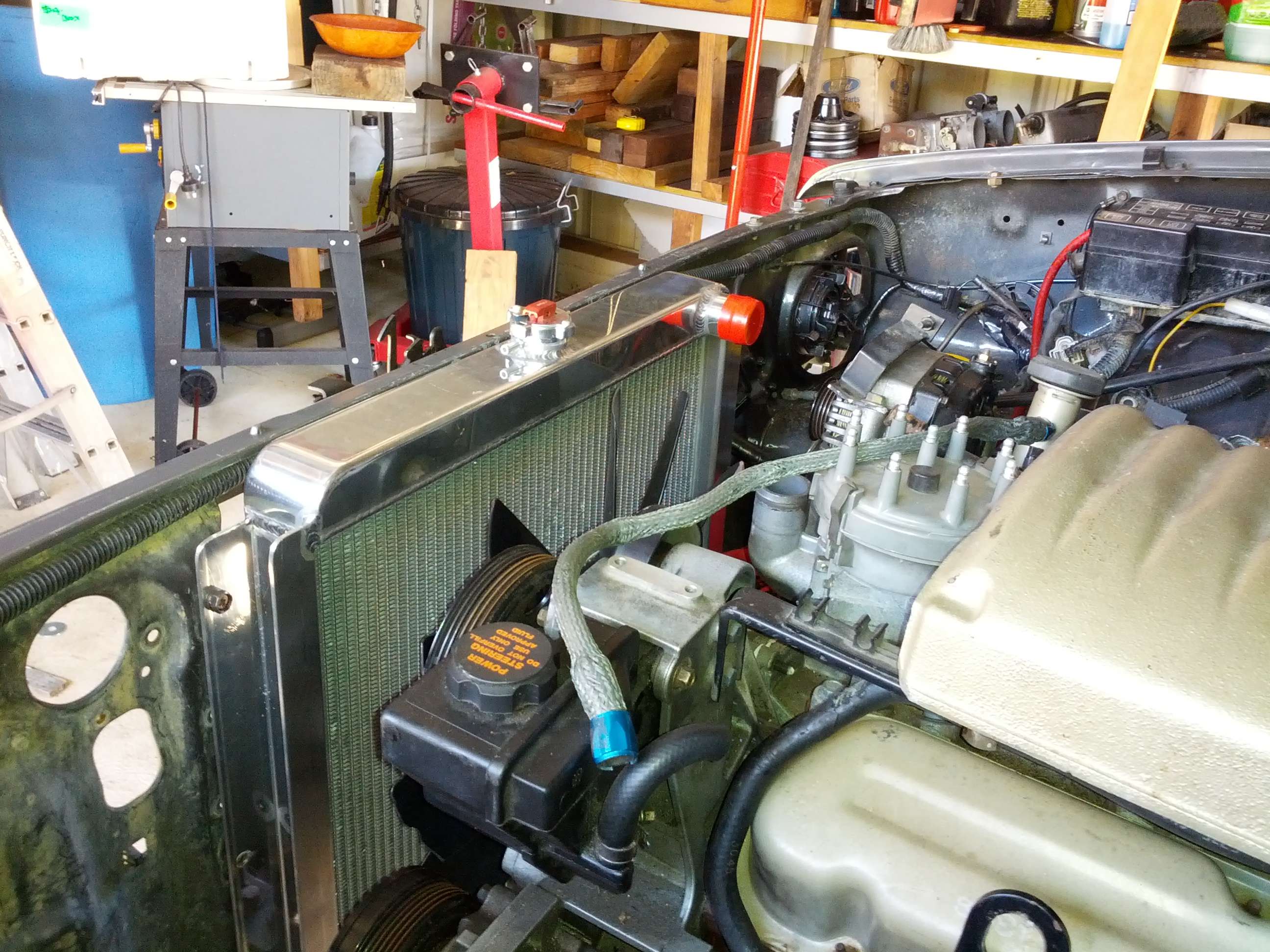

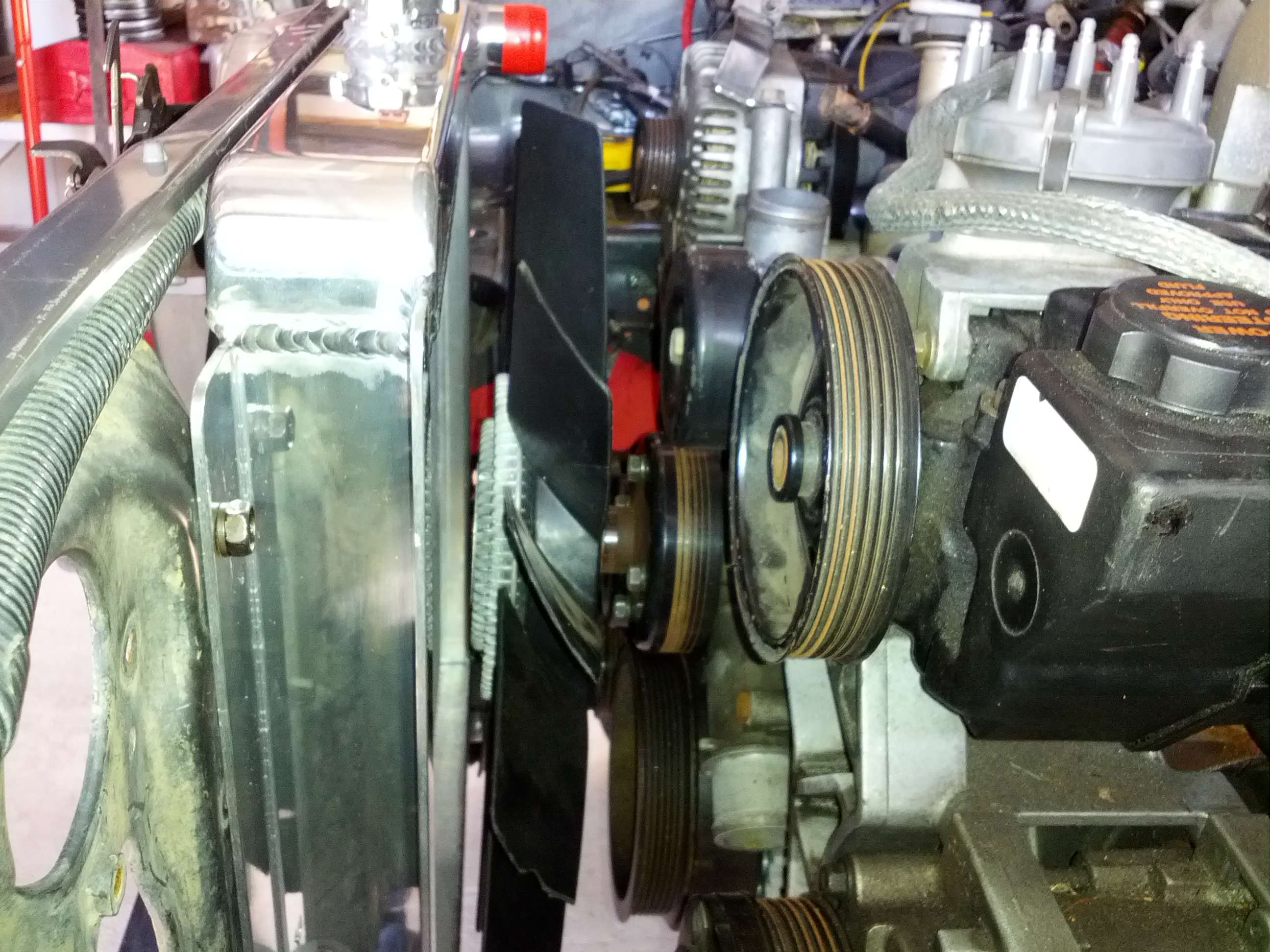

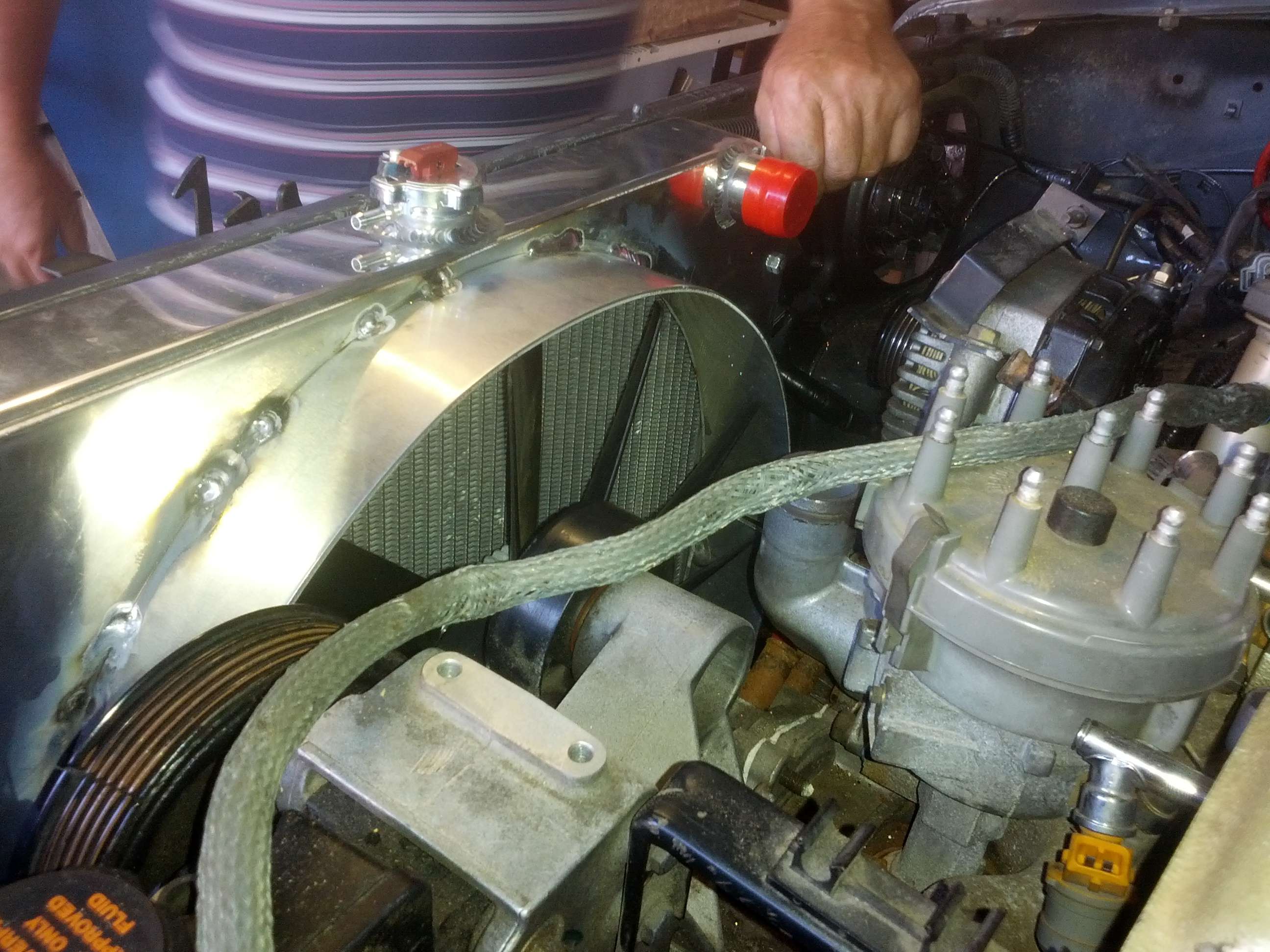

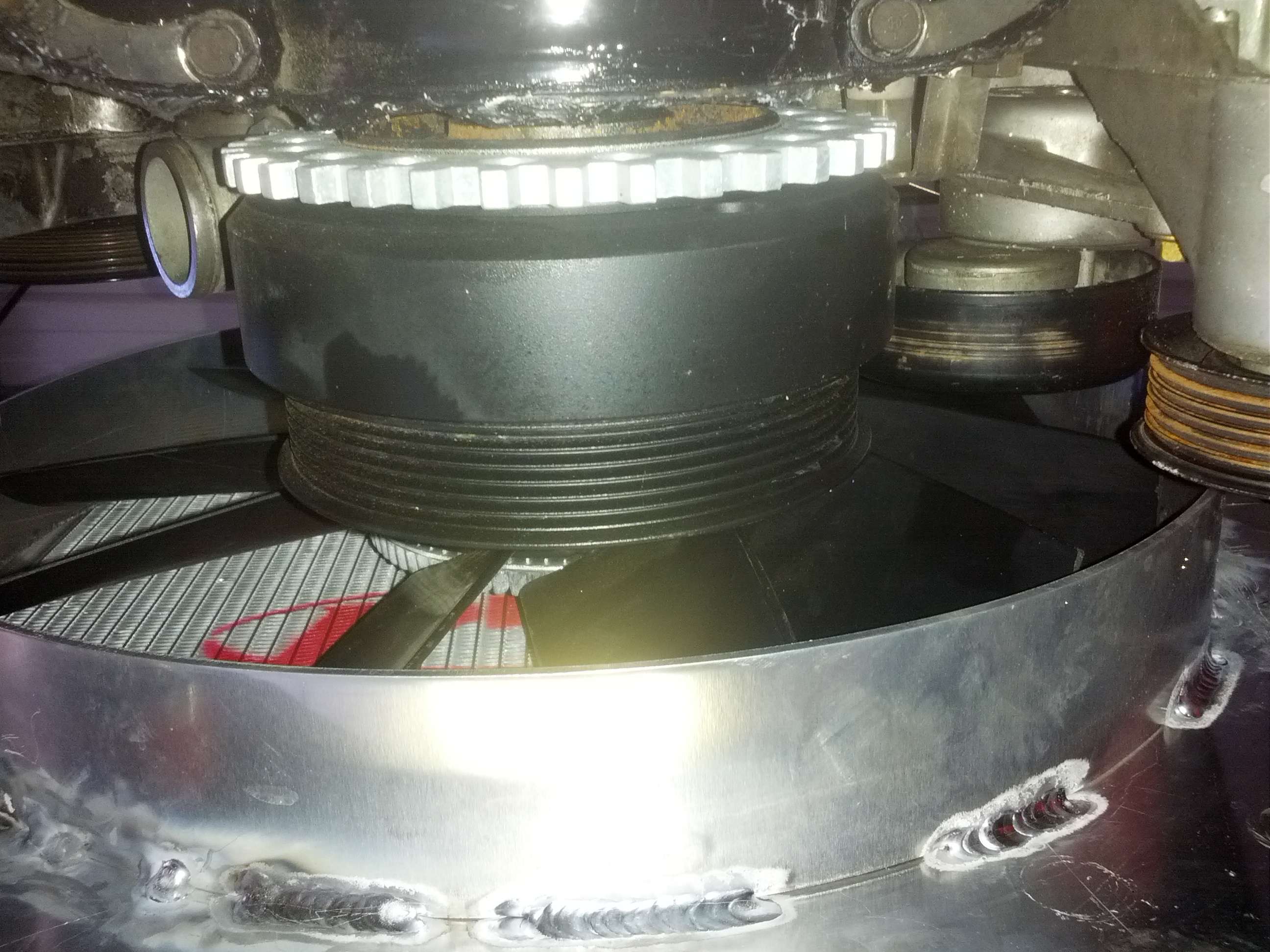

And now we move onto the Radiator.

And a rough idea of fan clearance.  (Not to worry about the chipped fan blade. A replacement is on the cards once everything is fitted up) The good thing about a radiator with an offset core is that making a fan shroud is quite simple. Simply a sheet of aluminium  And another sheet cut up and bent into a ring  Hey the welding aint much chop but it was the first time tigging aluminium in over 2 years. I'll clean it up with a dremel and give it another go later on. And here it is in the car.   One problem is that there is not enough clerance on the top side of the fan compared to the bottom. I'm considering 2 options at this stage. Option 1 is to raise the radiator and fan shroud together by 10-15mm. (at the moment the top of the radiator is sitting flush with the support panel. I don't know how much I can lift the radiator by before it touches the bonnet). Option 2 is to remake the shroud (practise makesa perfect but it can get expensive). A master tight a*** suggested a third option and that was to file down the fan blades equally until the desired clearance was achieved. |

||

| Top | |

||

| xcabbi |

|

||

|

I also made a start on the remote mount oil filter kit to see exactly how much room I had for a crossover pipe.

I used one of my old plastic body lift blocks as a guide and it seems that theres plenty of room for a 2" pipe between the engine mount and where the oil filter used to be. I also ordered a genuine block entry dip stick from summit so I got the correct oil level and also an idea of how to run the exhaust with the dip stick in place.  Filling her up with oil and its getting up towards 8L in capacity instead of the estimated 6.5L earlier on. |

||

| Top | |

||

| Matt_jew |

|

||

|

Can you not just move the top section of the shroud up the required amount and then put a filler plate in the middle?

_________________ {USERNAME} wrote: More people paid for a ride in a VT commodore then an AU Falcon so the VT is superior.

Based on that fact my Mum is the best around! |

||

| Top | |

||

| Who is online |

|---|

Users browsing this forum: No registered users and 50 guests |