|

| xcabbi |

|

||

|

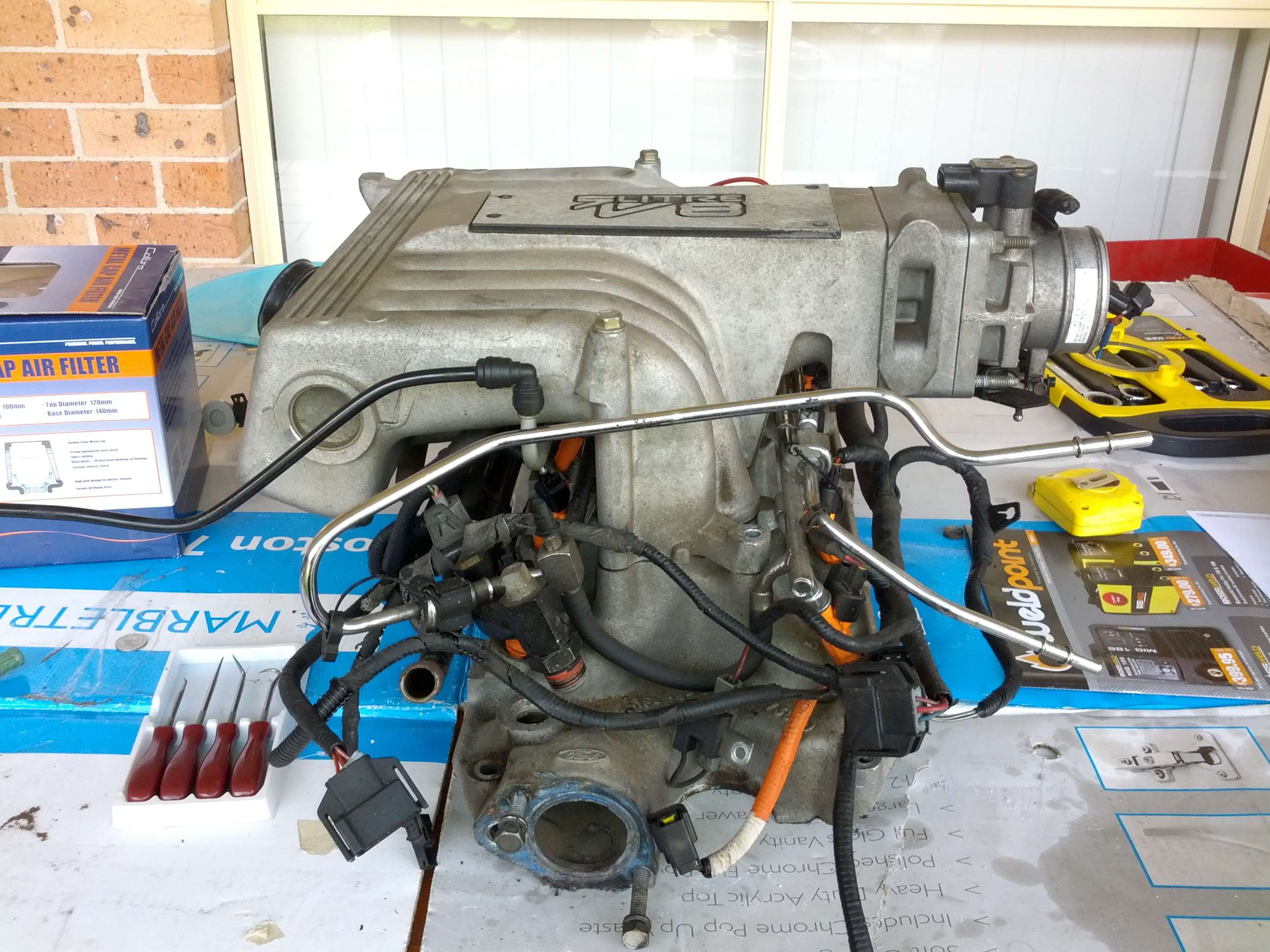

Well this came up at the right price (just over 1/2 the price of what the wreckers want for an incomplete unit) so I thought "why not, an exporer intake full of boost can still split the stock block".

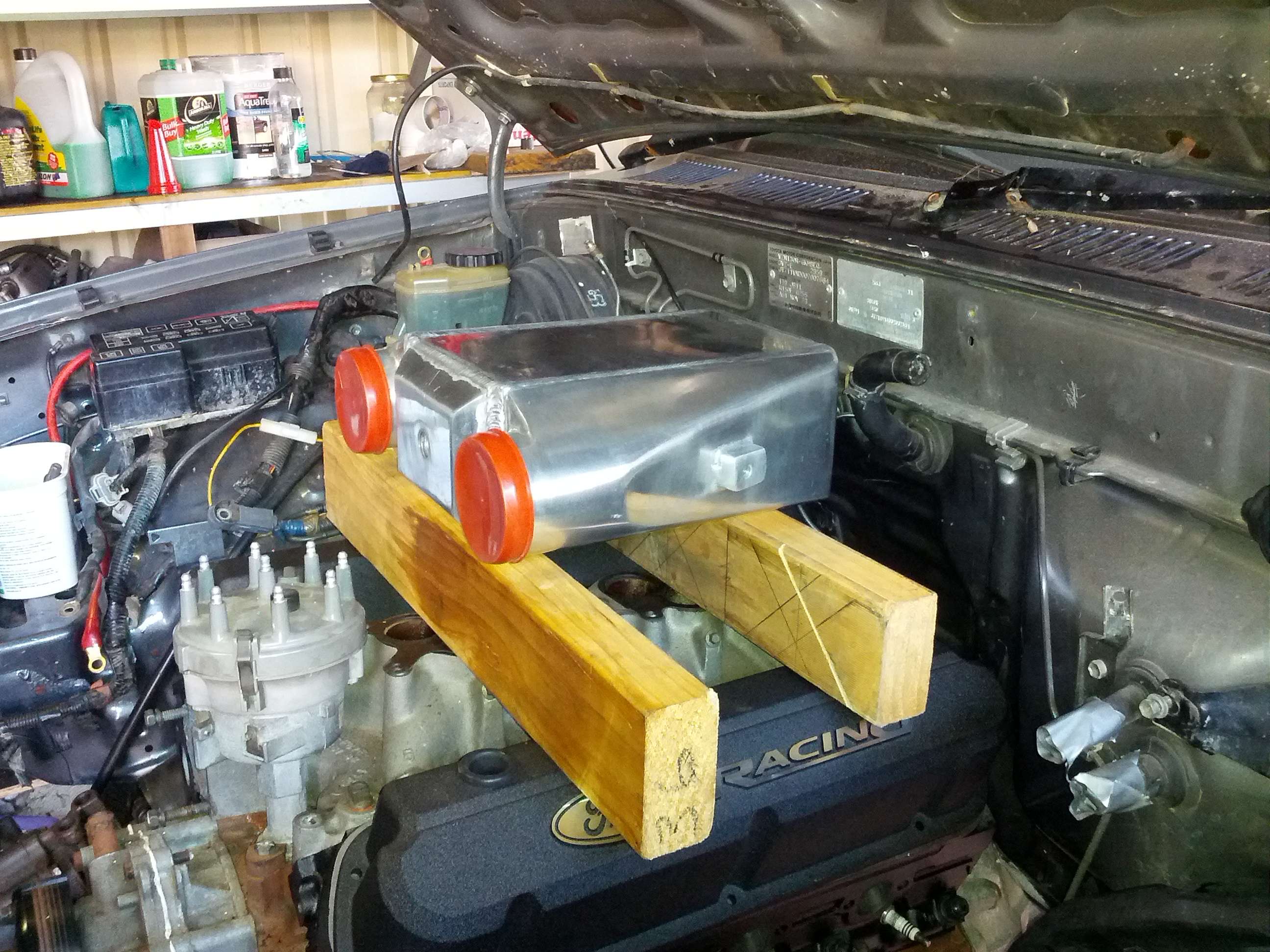

About the time this was all happening the water to air cooler came in the mail. 12" x 11" x 4.5" unit from CX Racing in the states. The core size is 11" x 6" x 4.5" so its 1" bigger than the equivalent cooler from frozenboost but its overall dimensions are slightly smaller (end tanks are a bit more compact). Now the problem is, where do we put the damn thing? Option 1 move the battery to the boot and fit the cooler in its place?  Or do we fit it as a top mount and cut a hole in the bonnet (protected by a reverse cowl scoop)? A real tower of power.  This gives a fair idea as to how high it sticks up past the bonnet line.  My field of vision doesn't seem to be affected too badly at all.

|

||

| Top | |

||

| xcabbi |

|

||

|

{USERNAME} wrote: Can you not just move the top section of the shroud up the required amount and then put a filler plate in the middle? I could but then it might get a bit too close to the radiator cap lol, I'll have a closer look at it possibly later on this week. |

||

| Top | |

||

| Johnson stroker |

|

|||

|

mount it where the passenger seat is currently, nobody will ever be crazy enough to get in the car with you sober. Thats why you work so well as a Cabbie.

_________________

|

|||

| Top | |

|||

| D.J. |

|

||

|

The bottom of my rad is about 15mm ABOVE the bottom of the front x-member and still clears the bonet.

I did this to be able to run hard power steer lines under the rad to keep it a bit neater. HTH. Heading down to Tuff Truck in a few weeks, if I have enough time, will call in and see how your going and you can see how I did mine. |

||

| Top | |

||

| xcabbi |

|

||

|

Cause of my body lif it throws things out for me. I just need the the top of the radiator to radiator support panel distance as a guide.

I've got plenty of cleance under the radiator for PS lines and the like. Thanks for the offer Douggie. Who knows I might come up to tuff truck myself depending on time. |

||

| Top | |

||

| D.J. |

|

||

|

If you have 50mm BL, them you can go 50mm higher than me from x-member I guess.

|

||

| Top | |

||

| xcabbi |

|

||

|

You are right. I got so consumed in thought that I overlooked that point.

|

||

| Top | |

||

| xcabbi |

|

||

|

Its been a while since I provided an update so I decided that its time for one.

First things first. I bought a set of GT40P heads which I had reco'd and fitted with crane behive springs and crane 1.72 Roller rockers.  I also fitted an ARP stud kit and Victor Reinz solicor head gaskets. I thought I might tart them up with a coat of satin black engine enamel and they came up better than expected. This forced me to think about colour coordination (more on that later). Roller rockers need decent rocker covers so I shelled out for a set of proform slant edge jobbies in black crinkle finish. Also since I planned on flipping the upper around the standard fuel reg was in the way so I decided to get a malory fuel rail kit and be done with it.

|

||

| Top | |

||

| xcabbi |

|

||

|

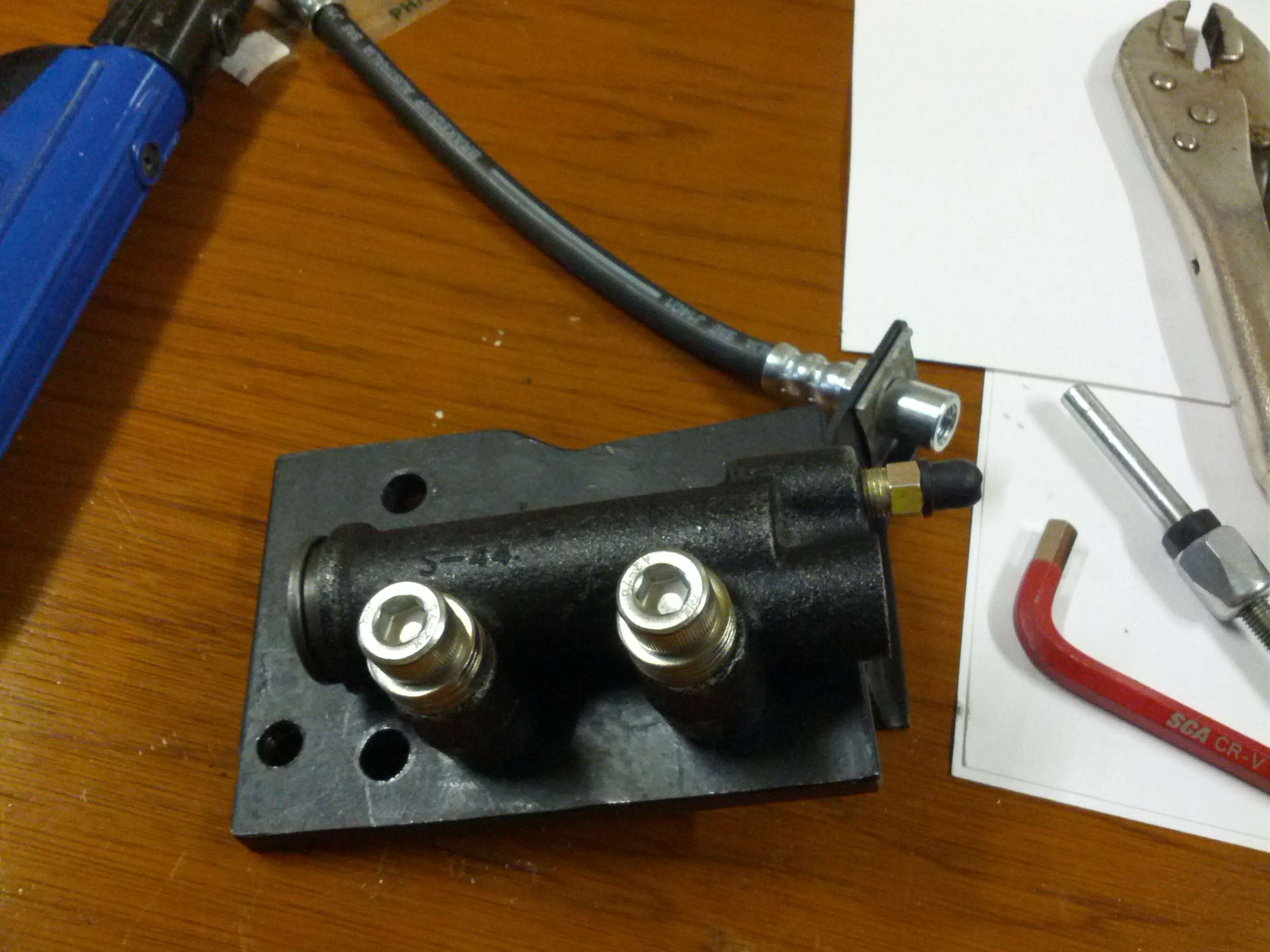

I mentioned earlier that I was going to go over the differences with clutch cylinders and pedal boxes so here is what I learnt after a few trips to the wreckers.

Internal vs external clutch master cylinder.  Pedal boxes for external and internal clutch master cylinders.  VZN130 (left) and FJ62 slave cylinders with an assortment of pistons and springs.  From left to right they are: factory 4runner, reproduction 4runner and reproduction FJ62. All are the same external dimensions but they each have a different cut out in the front of the piston to accomodate the pushrod. Even the factory and reproduction 4 runner pistons are different. Also all 3 have different length springs. I just picked one that would have the piston sitting the correct height in the bore without popping it out when I put my foot on the clutch. Note that the dellow adjustable pushrod is fitted to the FJ62 clutch slave. |

||

| Top | |

||

| xcabbi |

|

||

|

Dellow weren't exactly spot on with their slave cylinder mount bolt holes and since I decided to go with a 60 series master/slave combo I had to do a bit of Macgiver work (been a lot of that during this build).

First thing's first. I had to cut off the tab on the side of the sandwich plate and the ridge on the bellhousing.  Space was tight down there so I had to alternate between a hacksaw blade and one of those cheap multi tools to get it all as flat as possible. Getting there  Done

Last edited by xcabbi on Wed Nov 06, 2013 10:37 pm, edited 2 times in total. |

||

| Top | |

||

| xcabbi |

|

||

|

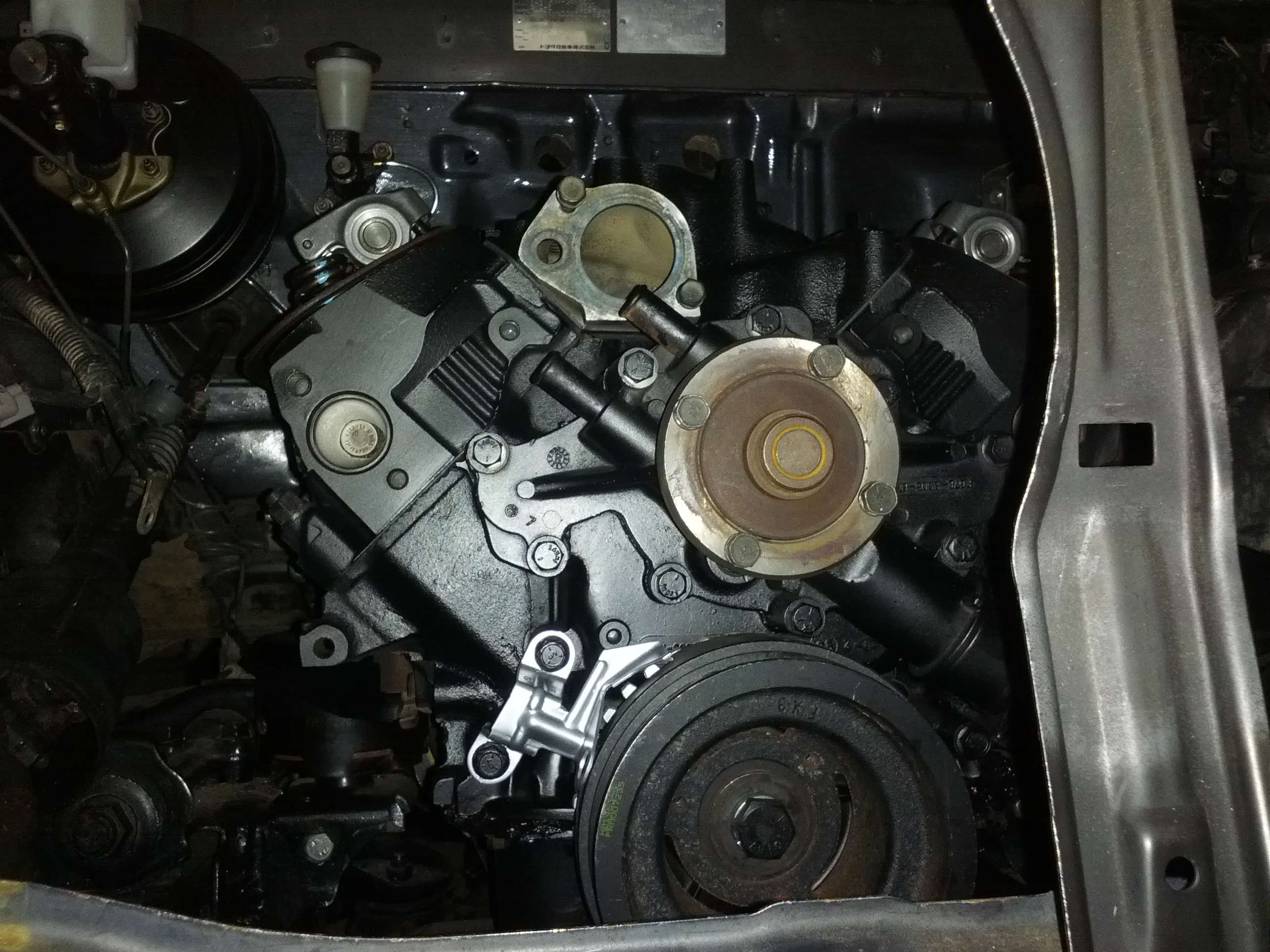

It would have been nice to have the correct sized hole for the clutchfork boot.

Looks like an offcut of sheet alluminium sickaflex'd in position will have to do. Once the bellhousing and sandwich plate were cleaned up it was time to start working on the slave cylinder bracket.  It took quite a few attempts till I was reasonably happy with the pushrod to fork angle throughout its stroke. Once it worked out it was time to fab up the bracket.

|

||

| Top | |

||

| xcabbi |

|

||

|

Pedal box removal in these things is by no means easy and sometimes you have to do keep removing bits and pieces untill you have enough room to work with.

It wasn't all that bad. I took the time to replace the foam in the fan, aircon and blower boxes as well as replace my AC condensor, TX valve and perform a minor repair to my heater core (crushed one of the tubes when lowering the engine back in). One thing to note is that rusty support brace appears to be slightly different according to hilux and 4runner. My pedal box came from a hilux and my brake light switch fouled on that brace. A bit of notching and I was on my way again. The foam was that bad you'd touch whatever was left of it and it would just crumble.  All done with new foam now. Hopefully it lasts a while.

|

||

| Top | |

||

| xcabbi |

|

||

|

Since I'm set on going turbo I bought Daz's old intercooler (top one) off him with the possiblilty of using it if space became a problem

. .I also contemplated a small box plenum to keep everything under the bonnet.  But my bonnet scoop calculations allow me to go up to 8.6" tall with a 2+2 lift on a 29" highway tyre and still be legal so I thought stuff it. Time to build a real tower of power. Man you have to love the short downward sloping bonnet (compared to a long flat one on a GQ patrol) and elevated seating positon of the 2nd gen 4runners and hiluxes. It was about this time I could no longer stand the look of lovely black heads being propped up by a cast iron block covered in rust so I thought I'd do something about it.  The colour scheme was now decided to be low gloss satin black engine enamel and liquid chrome in a can for the highlights. Surprisingly it looks pretty decent. |

||

| Top | |

||

| xcabbi |

|

||

|

And those rocker covers didn't fit so easy. The firewall neaded a fair bit of work with the porta power to get some clearance.

|

||

| Top | |

||

| xcabbi |

|

||

|

The intake manifold didn't escape the wrath of the rattle can either.

Whilst the accessory brackets copped a bit of rattle can abuse too.

|

||

| Top | |

||

| Who is online |

|---|

Users browsing this forum: No registered users and 178 guests |