|

| Matt_jew |

|

||

|

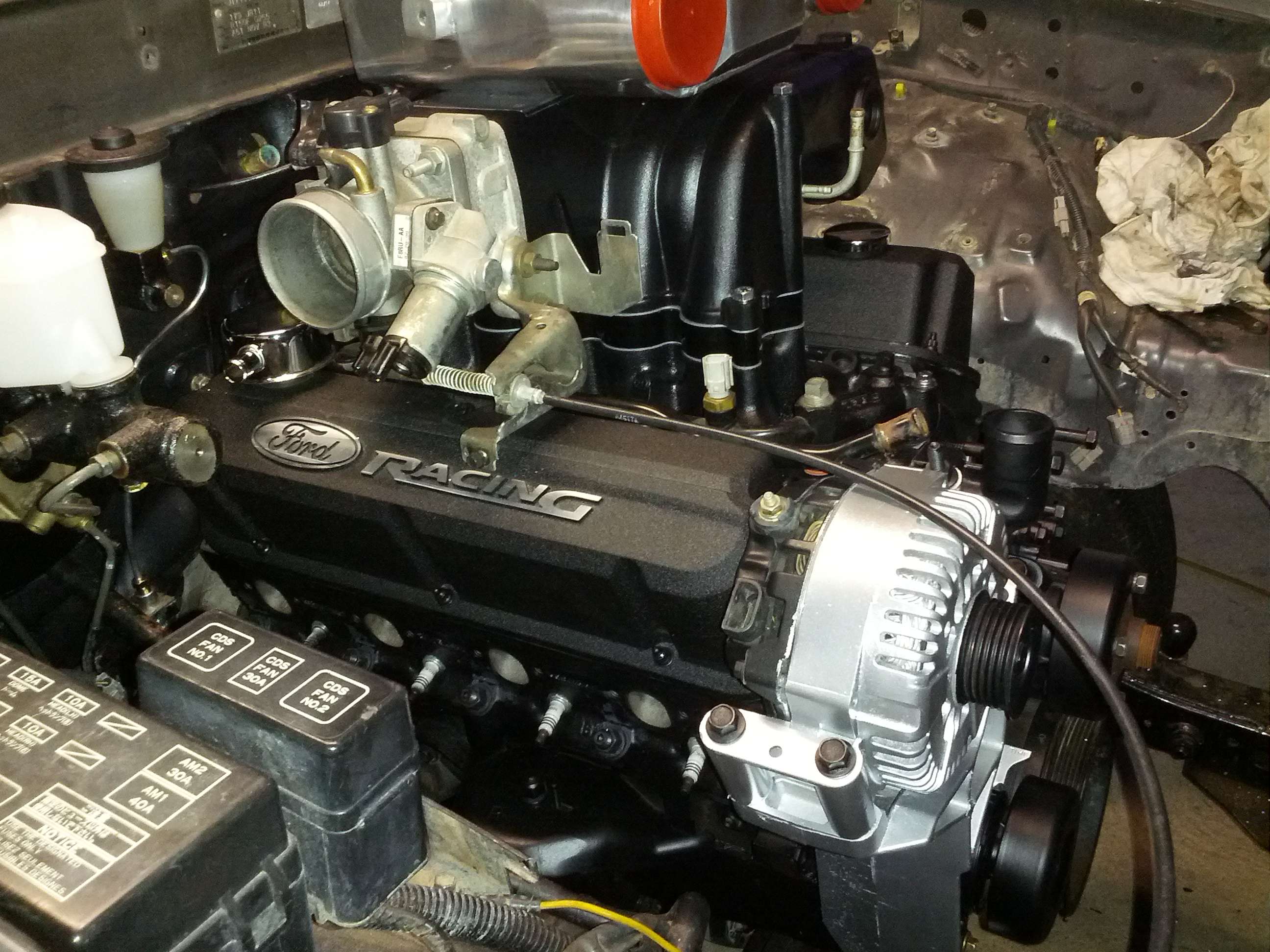

Looking very tidy.

Keep plugging away.

_________________ {USERNAME} wrote: More people paid for a ride in a VT commodore then an AU Falcon so the VT is superior.

Based on that fact my Mum is the best around! |

||

| Top | |

||

| xcabbi |

|

||

|

And here we are with some of the bracketry dummied up

|

||

| Top | |

||

| xcabbi |

|

||

|

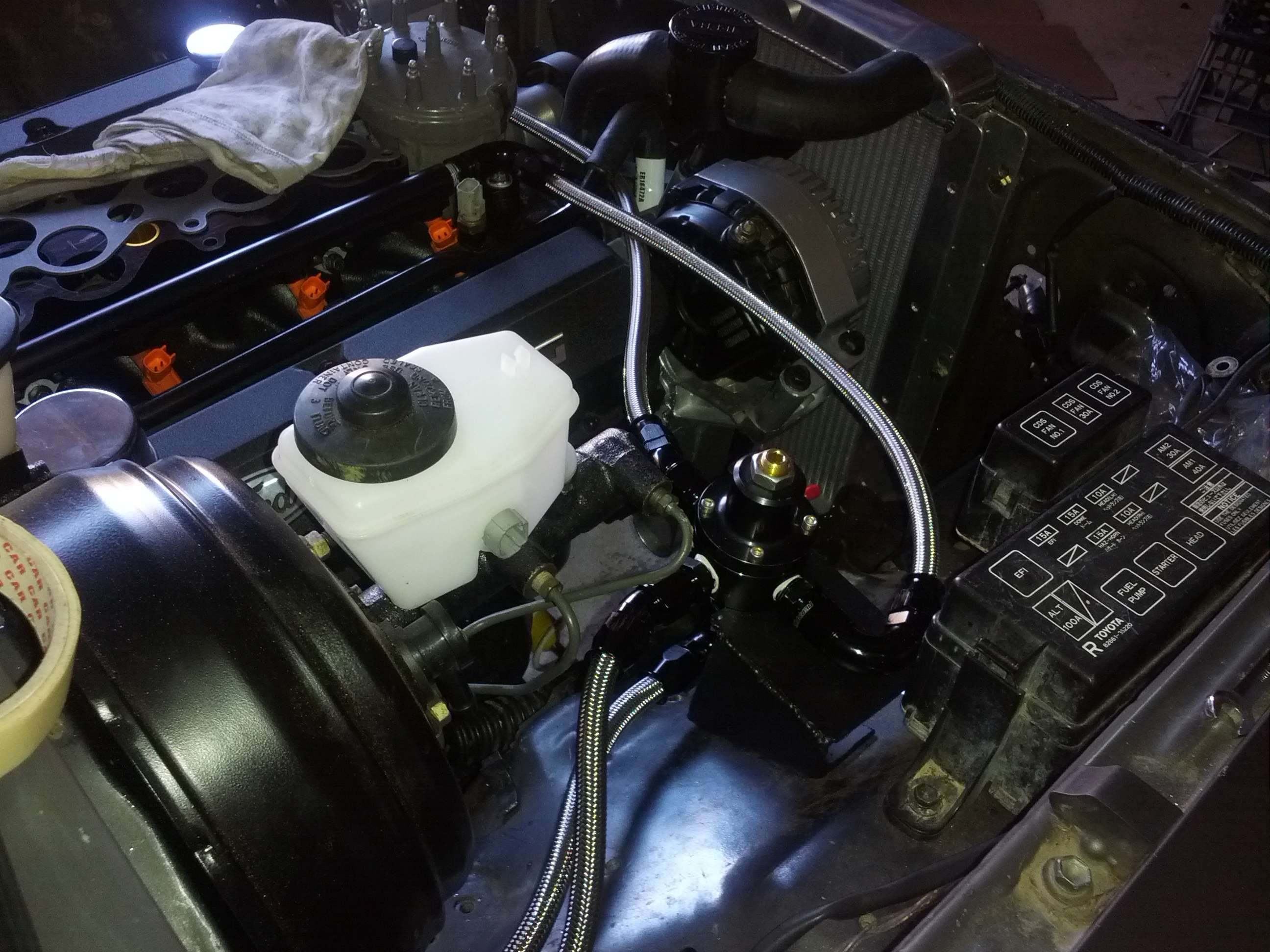

With the conversion to E85 (even if its just for the emissions test and some street driving subject to availability) the engineer said I needed a fuel system rated for E85 use. New pump, lines, hoses and a sealed tank.

First thing was first. The stock 90Lph pump was in no way going to cut it so it was turfed in favour of one of the new walbro 460Lph E85 pumps.  The plan was to run -8 feed and return so the pump hanger had to be somewhat bastardised in order to accomodate everything.   Wiring is 14 gauge IIRC with with some JB weld around the gromet to make it seal. The tank wasn't in too bad of a shape considering the only fuel I ever used was E10  But it still needed a clean and seal.

|

||

| Top | |

||

| xcabbi |

|

||

|

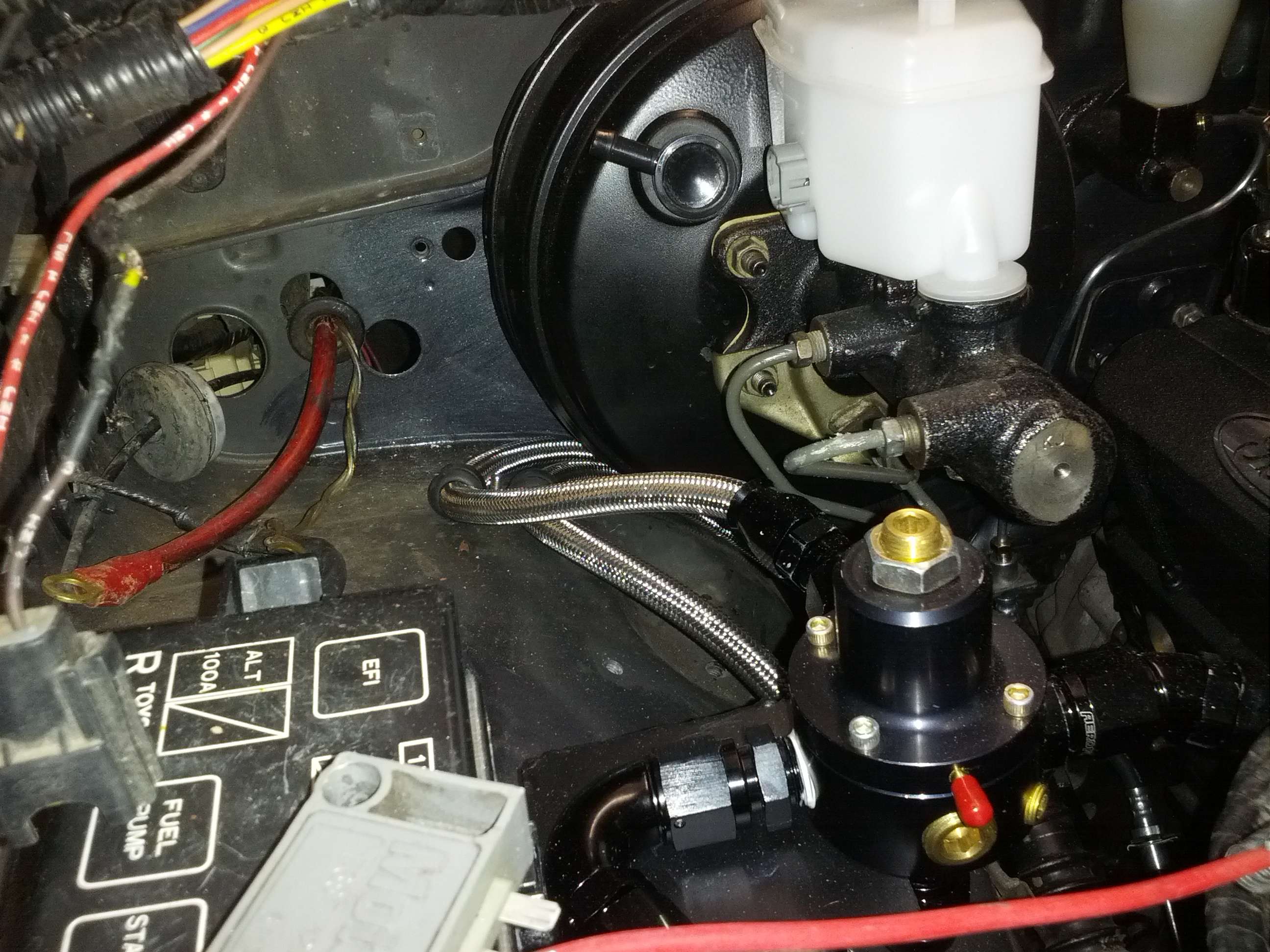

$1200 odd worth of braided hose, fittings, clamps and alloy hard lines later and we have what appears to be a fuel system that can support a touch more than stock power levels.

Had to use Braided line under the handbrake cable

|

||

| Top | |

||

| xcabbi |

|

||

|

And now the piece de resistance courtesy of Da22le from Dazfab fame.

First we dummied up the turbo location till we found something that was workable.  And then the master got to work fabbing away.    The turbo is a GT3582R with a 1.06 rear housing and 0.7 front housing. Pipe size is 1 3/4" primaries going to modded difilipo collectors into a 2" crossover and then meeting up to a twin 2" turbo entry. I know the primaries are too big but it was part my fault as I had ordered the kit for an NA car before I decided to go turbo and difilipo were ramming the 1 3/4" kit down my throat even though I enquired about the 1 1/2" and 1 5/8" kits. Still to fab is the wastegate plumbing for twin 40mm comp gates and a 3" dump pipe. God willing it will be done next Saturday. |

||

| Top | |

||

| xcabbi |

|

||

|

Thought I might post an update since its been a long time between drinks.

As promised here are some pics of the twin 40mm wastegate setup and 2 piece dump pipe.     That's all Daz's handy work. Same can't be said for mine. |

||

| Top | |

||

| xcabbi |

|

||

|

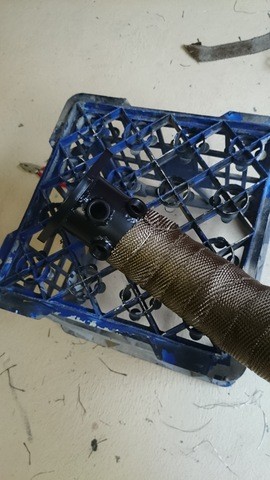

On a side note this is how tight a fit they are on an E7 head with 90 degree boots.

Definitely a header out job to change the plugs on any head except for GT40P or World Windsor Sr. With the GT40P's I only need to remove one part of the crossover pipe (that bit that goes between runners 5 and 6 and has the lower wastegate attatched to it) to get spark plug 5 out. Conventional socket clears all of the other runners quite easilly. And now onto the dump pipe. I didn't know how much of a pain in the a*** aluminised tube was to weld with a tig. Anything over 33 amps and I'd burn a hole through almost straight away. Anything under 30 and I'd have a nice looking but cold and weak weld. Pulse helped me out heaps. After a bit of mucking around I got soemthing that held together but looked no where as near as pretty as the top half of the exhaust.   All up I moved the cat about 60cm forward from the stock location to try and get as much heat into it to get good emissions.  The whole lot is getting ceramic coated in Turbo X black at competiton coatings at the moment. Should be done by the end of week. I also plan on wrapping it on top of the ceramic coating because I don't want to be melting spark plug leads every time I lean on the throttle. In the mean time I have a set of Seimens Deka 60lb injectors and PMAS-HPX 3" blow through maf that have just arrived. |

||

| Top | |

||

| DA22LE |

|

|||

|

Pretty sure I mentioned that you can't wrap a ceramic coating.

Just get some boots for the ignition leads. Keep at it old mate.... Cheers Daz

_________________ BA XR8 Boss 260 |

|||

| Top | |

|||

| xcabbi |

|

||

|

There's a guy on the turbo forums in the states that coated and wrapped his pipes and reported no problems.

I guess when you've got someone like Brett saying they can't get a set of leads to last over 2000's because they just melt it kind of makes me feel a bit uneasy. I'll ask the coaters what they think when I pick everything up. Funny thing is they are also coating the flex joint for me and the exhaust shop that I got the joint from said it's impossible to coat flex joints, especially braided ones. |

||

| Top | |

||

| galapogos01 |

|

|||

Posts: 1139 Joined: 27th Feb 2005 Ride: Supercharged EF Fairmont Location: T.I. Performance HQ |

I've wrapped my ceramic coated headers. They've been that way for 2+ years and 10,000+km and so far so good.

Nice build! Jason

_________________ {DESCRIPTION} - {DESCRIPTION}, {DESCRIPTION}, {DESCRIPTION}, {DESCRIPTION} and more! |

|||

| Top | |

|||

| xcabbi |

|

||

|

Thanks

And you know what is more interesting about this build Jason? I bought a J3 chip from you about 2 years ago for this very build. This was before I decided to go turbo. I'll be getting a chip programmer and a few other things before I'm ready to kick it over. |

||

| Top | |

||

| alby1 |

|

||

|

Interesting build, will have to go through it when have more time. Exhaust headers look good.

_________________ EL XR8 II Manual, Ported GT40P's, E303 cam, Au220TB, 70mm MAF, HiFlo Cats, Tune (215rwkw) and some bigger brakes |

||

| Top | |

||

| FAT245 |

|

||

|

Looking f**k awesome nik!

_________________ Daily: My 342Cu.In AU Fairlane with ESS 278.3 RWKW |

||

| Top | |

||

| xcabbi |

|

||

|

Thought I might provide everyone with an update.

Got the headers back from the coaters and I must say they came up a treat.  I asked them about wrapping a coated exhaust and they were fine with it since they coat multiple layers on the inside and out (single/double on the inside and tripple on the outside). All of the issues with moisture and rust are non existant. The only real problem would be a fatigue issue on a setup that will be subject to high boost for prolonged periods of time. The heat would build up in the walls of the exhaust and not be able to escape as it would be reflected between the wrapping, the outer ceramic coating and the inside ceramic coating. Since this motor is a low boost streeter (for the time being) with the odd lean on the throttle I don't see an issue with it. So I went out and got them wrapped in DEI titanium exhaust wrap. Man that stuff is itchy when you cut it. Not as bad as fibreglass but still a pain in the a***.  Credit where credits due  And all the way down to the end of the dump pipe. Should keep them exhaust gasses hot and let the cat converter do its thing.

|

||

| Top | |

||

| xcabbi |

|

||

|

I also got around to welding some mounting tabs on the intake manifold and the cooler. Should be able to start piping it all up soon. In the mean time it looks like a cross between Wall-E, Johnny 5 and a HK tank.

|

||

| Top | |

||

| Who is online |

|---|

Users browsing this forum: No registered users and 50 guests |