|

| Matt_jew |

|

||

|

{USERNAME} wrote: I already feel sorry for the next person to get their hands on my Paj It will only be an insurance assessor wont it? They are the scum of the earth anyway so f**k them.

_________________ {USERNAME} wrote: More people paid for a ride in a VT commodore then an AU Falcon so the VT is superior.

Based on that fact my Mum is the best around! |

||

| Top | |

||

| xcabbi |

|

||

|

D.J or ozrunner, can either of you guys give me the dimensions of the pwr radiator? The dimension I need at the moment is the thickness.

|

||

| Top | |

||

| ozrunner |

|

||

|

I made an actual mockup to get the right clearances and then sent the dimensions to PWR to have it custom made etc.

Core is 32mm(Corrected) Tanks are 60x40mm Total height 540mm Total width of actual rad 515mm(Not including mounts) Last edited by ozrunner on Sun May 20, 2012 11:13 pm, edited 2 times in total. |

||

| Top | |

||

| xcabbi |

|

||

|

Thanks for that.

With the engine hard up against the firewall I have about 140 mm from air con condenser to water pump pulley, and that's the mating surface where the viscous hub would sit. Also since you went from auto to manual did you use the standard 4runner master and slave cyl combo? With my dellow kit I was given a clutch fork based on a holden torana. Being a longer unit I'm a bit worried I might run out of travel before I disengage the clutch. I've heard a remedy is to use 80 series landcruiser master and slave combo. |

||

| Top | |

||

| ozrunner |

|

||

|

{USERNAME} wrote: With the engine hard up against the firewall I have about 140 mm from air con condenser to water pump pulley, and that's the mating surface where the viscous hub would sit. This rads core will sit flush with the side body mount panels so screw the fan on and measure the space from the bottom fan blade to these panels and subtract 42mm to see what final fan clearance you will have. Note that you will also have to have enough to be able to unscrew the fan with the rad in place in order to then be able to remove it etc. I use a 75 series clutch master and slave with a modified angled Ford lever and a Ford top loader boot. But I also modified my actual clutch lever throw and then determined what slave bore diameter to use to obtain the necessary throw with this master. I also made my own fibreglass 2 piece shroud. I unbolt the top section, remove the fan and the rad slides out easily. JD

|

||

| Top | |

||

| ozrunner |

|

||

|

Correction on Rad core width. Is is 32mm. DJ queried it with me as his is 32mm.

I took the 42mm off the initial CAD drawing sent to me by PWR for final approval but now recall that after discussing it with them they recommended I go for their new dimple core which is 32mm as it would also allow an additional 10mm clearance. |

||

| Top | |

||

| xcabbi |

|

||

|

No worries. Should aim to have some mounts made up over the next day or two.

|

||

| Top | |

||

| xcabbi |

|

||

|

Got the motor mounted into position with nothing more than 100mm x 75mm RHS. Have to slot the passengers side to bring the motor across 10mm but other than that I could not be happier with the position. Pics to come later on tonight.

|

||

| Top | |

||

| low_ryda |

|

|||

|

Awesome. I was surprised at how easy it was to mount the chev in my brothers cruiser. Although we had a fair bit more room to play with in the 45. Basically an rhs/plate combination but.

Look forward to seeing more pics. Have I missed what box you're putting behind this?

_________________ Not to get technical, but according to chemistry alcohol is a solution. |

|||

| Top | |

|||

| xcabbi |

|

||

|

Standard R150F box will be strong enough.

|

||

| Top | |

||

| Johnson stroker |

|

|||

|

It's later, where are the pics?

_________________

|

|||

| Top | |

|||

| xcabbi |

|

||

|

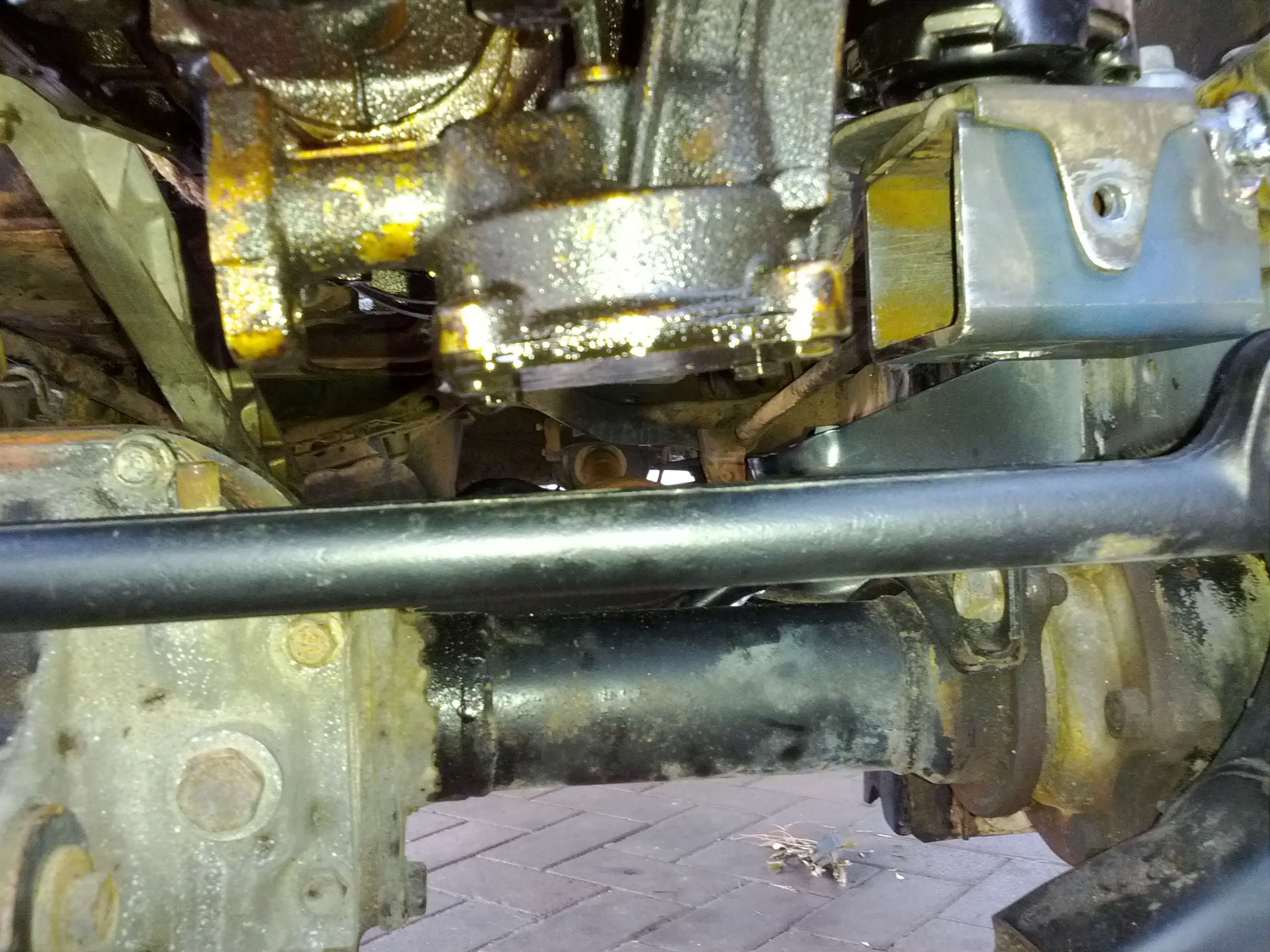

Just for you Dave

The mounts are by no means aesthetically pleasing but they are there to do a job.  I blew a hole through the top and bottom with a plasma cutter so I could fit a socket through the bottom of them to to tighten up the nut on the under side of the mount. Not pretty but it does the job. The jagged bit on the bottom is cause the clamp on my superworks drop saw couldn't hold anything. That will all get cleaned up with a grinder. I'm relatively pleased with the weld across the top but I'm far from happy with the front and back vertical welds. Will fix them up either tomorrow or Sunday. Also need to weld in some gusset plates to support the overhang.

|

||

| Top | |

||

| Matt_jew |

|

||

|

Thats looking alright for a shonky goat f**k.

Well done.

_________________ {USERNAME} wrote: More people paid for a ride in a VT commodore then an AU Falcon so the VT is superior.

Based on that fact my Mum is the best around! |

||

| Top | |

||

| hans hartman |

|

||

|

{USERNAME} wrote: Just for you Dave The mounts are by no means aesthetically pleasing but they are there to do a job.  I blew a hole through the top and bottom with a plasma cutter so I could fit a socket through the bottom of them to to tighten up the nut on the under side of the mount. Not pretty but it does the job. The jagged bit on the bottom is cause the clamp on my superworks drop saw couldn't hold anything. That will all get cleaned up with a grinder. I'm relatively pleased with the weld across the top but I'm far from happy with the front and back vertical welds. Will fix them up either tomorrow or Sunday. Also need to weld in some gusset plates to support the overhang.  looks like your moving to fast,its a slow process.vertical welds-did you start at the bottom and go up?they are hard to keep nice and even.what size is the weld?was it 1 run or 3 runs.

_________________ R.I.P HANS HARTMAN |

||

| Top | |

||

| xcabbi |

|

||

|

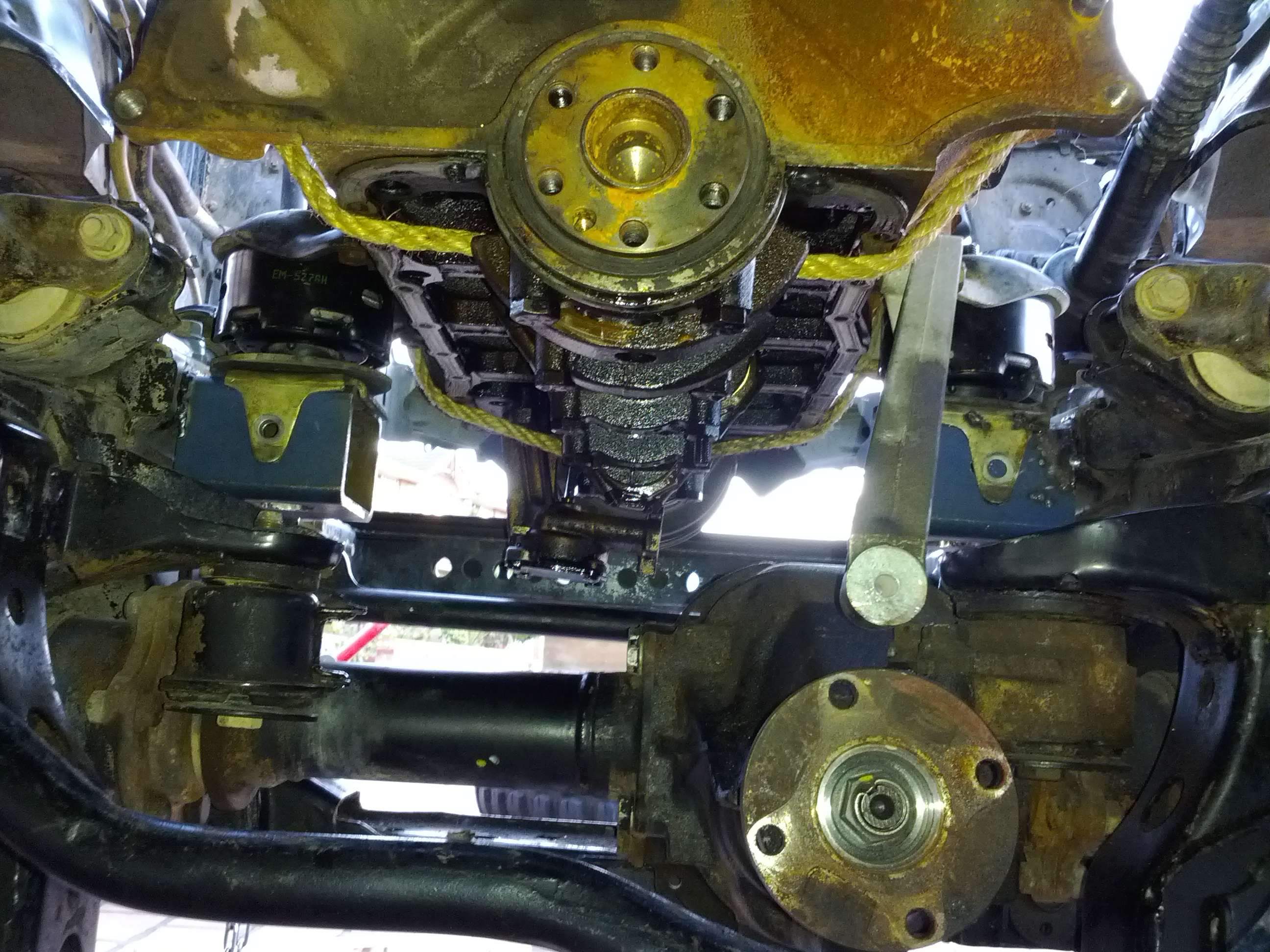

And now onto the final clearances.

Oil pump to steering arm  Trans Brace to Diff  Bellhousing bolt access  Passengers side head I can fit my fingers round the back.  Fan clearance That Piece of timber is a bit thicker than 35mm. I expect another 10mm or so clearance after fitting the AU water pump.  I also took the time to dummy up the AU alternator and idler pulley. What do you know it fits like a glove without fouling on the steering box like the E series Idler pully and tensioner.

|

||

| Top | |

||

| Who is online |

|---|

Users browsing this forum: No registered users and 147 guests |