|

| turbo_will |

|

||

|

So ive ended up selling my old red eb to a mate and moving on to a fresh project car, an ef futura. I picked it up for $500 off ebay with a suspected cracked head. Got it back on a car trailer, put a battery in it and it started but ran rough as guts and backfiring on LPG. Turns out the plugs were a million years old put in a fresh set and it ran not too bad.

So far ive removed the ef btr trans and fitted the eb btr with the TCI stall ive got for it which has been adjusted again and now stalls to 3100rpm with stock everything and is nice and tight still hopefully its on the money this time. First time was 2500rpm max, 2nd adjustment was way too loose, could hit the limiter on the brake lol. Ive removed all the LPG gear too, still need to pull out the tank. Ive got most parts from the old car to swap onto this one and a bunch of new gear. Yesterday i pulled the old head off the ef, it looked ok but its a bit too corroded around some water galleries. Ive got a good standard head off an el im using, cleaned it up and using my crow double springs and retainers/collets. Fitted it using 2x endurotec graphite $30 cheapy gaskets between 1.5mm decomp plate so compression will be fairly low. Also compression tested it before i pulled the head off and was all around 170-180psi not too bad for an old 276000kms motor. Any way its getting one of our mach2 series2 kits and the plan is to get it ready for the AFF drag day June 8th-9th at heathcote, so ive got exactly 2months to get it done haha bit of a rush. Plan is to beat last years effort 11.97@113mph. Bit of a run down on what im planning on running most stuff coming off the old eb... -Stock ef bottom end decomped -Crow springs and wade 1521a cam -j3 chip -60lbs injectors bp98 fuel -stock btr with TCI stall and trans cooler -std diff gears and mini-spool -3" exhaust -series2 mach2 turbo kit -ssi-4 dattalogger (afr, boost, rpm and egt) -surge tank feeding twin generic 044s (overkill for 98, was running e85 but maxed out injectors) -water injection 2xm10 nozzles (approx 1500cc per min) -275 MT et streets Thats all for now ill keep posted on progress.

Last edited by turbo_will on Sat Aug 31, 2013 11:34 pm, edited 4 times in total. |

||

| Top | |

||

| Saphiric |

|

|||

|

Can't wait to see the results...keep us posted!

|

|||

| Top | |

|||

| turbo_will |

|

||

|

Bit of progress today, finished the decomp off and got it running. Still drives ok but down on power over a stocker now from the low comp, has gone from 8.5-100kms to 9.5 haha and droped from 85mph to 80 over the 1/4. Adding timing will probably help heaps. Stall has also dropped from 3100 to 3000 rpm now.

Spent most of the day with wiring. Removed all the LPG wiring and computers then it wouldnt run, checked all cut wires finally found i missed one pink wire in engine bay. Once that was connected it run again. Also wired in aem wideband and egt gauges and connected ssi-4 dattalogger with 3bar gm sensor. Took it for a spin, still gotta play with getting the correct settings but it will be an awesome tuning tool once sorted. Was a laugh seeing the stock tune dip into the 10s afr at full noise! Last edited by turbo_will on Sat Mar 08, 2014 9:00 am, edited 1 time in total. |

||

| Top | |

||

| bry40l |

|

|||

|

hi turbo will, good to see your building another beast, wondering what you would sell the manifold for on its own? also just a turbo price on its own?

and do you make dump pipes to suit? been thinking about chasing the parts down individually when i have the money spare, was thinking about just buying your manifold and using a garret turbo, but will consider using your turbo depending on the price and if i ever score a decent garrett cheap thanks

_________________ BF XR6 |

|||

| Top | |

|||

| turbo_will |

|

||

|

PM sent bry40l

Small update got the ssi-4 to work correctly. RPM always worked accurately and so did 3bar map sensor but the afr and egt gauges were not recording correct datta. In the aem manuals it states the white wire is signal + and brown sig ground and to hook both these to dattalogger chanel. This dosnt work. After some mucking around i found the brown wire is actually the signal 0-5v so used this to dattalogger +input and put earth terminal straight to ground. All works as it should with correct values in the setup table. The logworks software is great to use. You can turn a log session into a chart displaying rpm/map with afr values the same as the tunerpro tables. Basically you van look at the chart and see at 5000rpm 0psi afr is 10.6 and then adjust that cell in tuner pro. Should save a crapload of time and guessing! Have the j3 installed now so the trans dosnt go into LHM with stally. Have it set to 5500rpm and it still goes into LHM stuck in 3rd on hard take of in 3rd and Drive. Just planting it is ok but if i hold the brake it goes straight to LHM. With selector in 1st its fine. Not sure if this is normal or not? Not a big deal really as i can just whack it in 1st for stalling and stand on the brakes/handbrake hard as. |

||

| Top | |

||

| turbo_will |

|

||

|

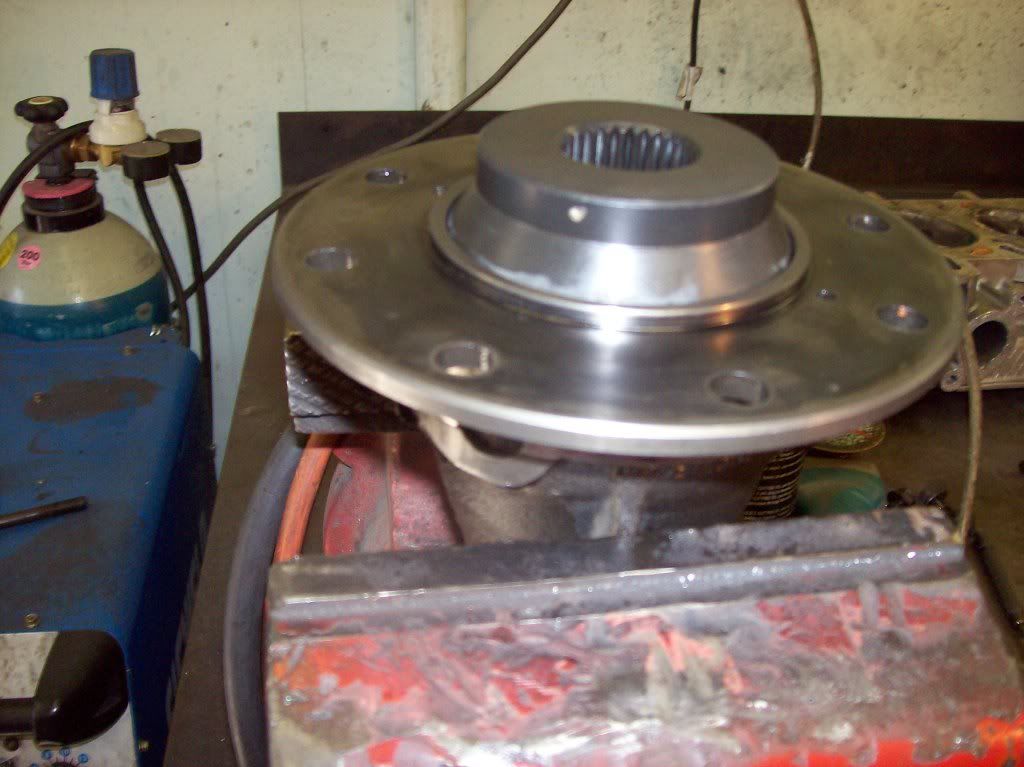

Yesterday i ended up fitting the mini-spool i got from tuffcarparts. Gears are stock 3.08

I also changed the front wheel bearings as they were shot. No wonder they died there was hardly any grease in them! Then i took it down to the servo and steamcleaned the engine bay and under car, it looks so much better now. Used 3 cans of degreaser as the k frame had a massive build up of crud on it. Also fitted the 60lbs injectors and started making a tune up for the ef ecu keeping the slope at 19lbs so i have plenty of fuel that can be added later under boost. Currently have ve table pulled back to low 20s at full throttle top end with 11afrts and stock fuel stab table so i should have plenty to play with on 98 fuel. The datta logging makes things a million times easier using the chart function, after just 5 burns starting from a guessed ve table the car is running prity well, idle still needs attention. For some reason with stock injectors and tune idle afrs were between 16-18 and it missed/stalled a lot. Now its way too rich still but it idles much smoother than when it was so lean.

|

||

| Top | |

||

| turbo_will |

|

||

|

Mucked around with this some more ive found a way get the idle leaner. Ive raised idle to 900rpm and its now idling at 12afrs in park and 13s in gear (was 9.5-10afr). This is with the ve table at 2 in idle cells at 600 and 900rpm and stab table at 22afr with slope at 19lbs still. The 900rpm idle wont be too bad i reckon as with the stall it dosnt move forward much in gear. I probably never came accross this in the eb as it idled prity high as the idle stepper motor didnt work and i used the screw on the throttle body to set idle. Its probably not the best way of doing it but im expecting i will now have heaps of fuel that can be added once boosted as ive always struggled to get enough fuel in under higher boost levels.

|

||

| Top | |

||

| turbo_will |

|

||

|

Today i removed the LPG tank, ran a 5g cable with 40amp fuse from the battery to the boot as a power feed for the fuel setup. Ran the water injection line next to the power cable with both wrapped in 13mm split tubing turned out prity neat. Fitted the surge tank and twin pumps, sorted out the wiring and fitted the water injection tank and wiring. Also fitted a boost gauge were the clock used to be using a gli insert. Next up is welding drain into sump and starting to fit the turbo kit up.

|

||

| Top | |

||

| turbo_will |

|

||

|

Got the drain in the sump mostly done just need to weld it in tomorrow. I took some photos of how i do it in situe, using a small punch first and then an air chisel with a tapered bit i made. Removed the stock exhaust too, turns out the cat was collapsed lots of chunks missing probably stuck in the muffler!

|

||

| Top | |

||

| ef_falcon_95 |

|

|||

|

Is the air chisel necessary ? Is a hammer and punch enough to pierce a hole through the sump ? Just wondering cos ill be doing mine this way . And you welding it with the sump in the car ??

_________________ El XR6 Turbo |

|||

| Top | |

|||

| turbo_will |

|

||

|

I use the small sharp punch to start the hole to about 10mm, i guess you could just use a huge punch and hammer it, i just use the air chissel because its easier. Yep welded in car, its a prick to do as theres not much room to get the welder in but beats pulling the sump off.

|

||

| Top | |

||

| ef_falcon_95 |

|

|||

|

Cheers u mig weld it

_________________ El XR6 Turbo |

|||

| Top | |

|||

| turbo_will |

|

||

|

yep mig, the sump is really thin, i only used about 100amps or so didnt want to hole it!

|

||

| Top | |

||

| turbo_will |

|

||

|

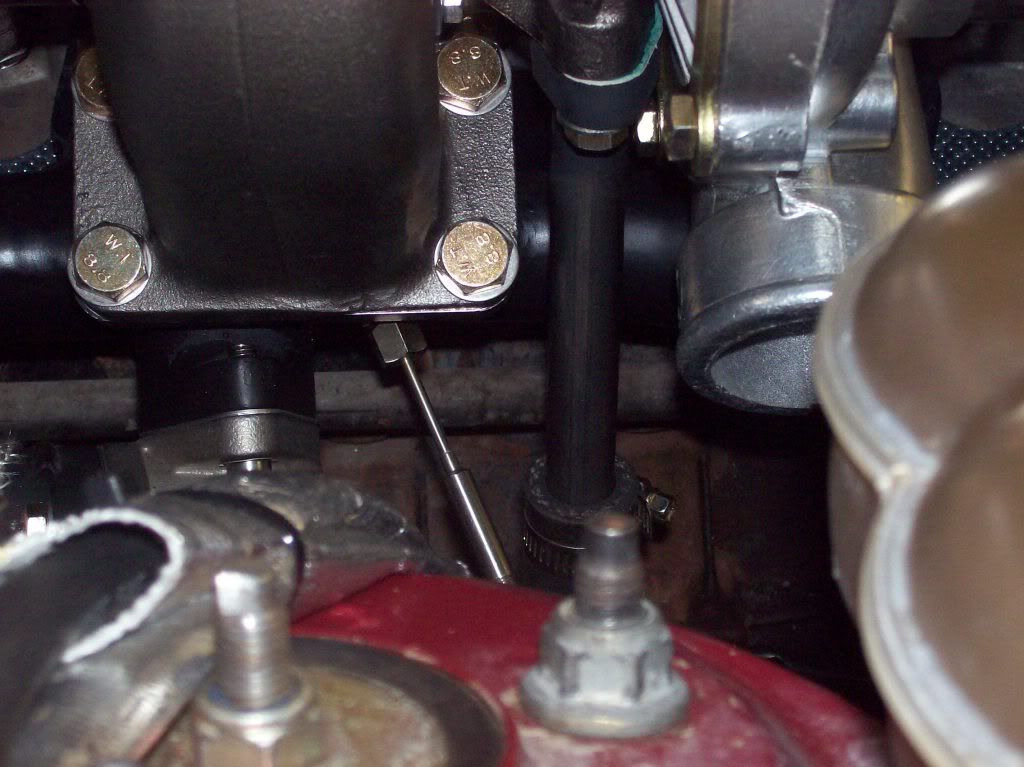

Finally got the turbo kit fitted up today! Started by heatwraping everything in eng bay and drilling/tapping the manifold for the egt probe. Fitted manifold and turbo up and joined dump pipe to the old 3" exhaust which is just one straight thru muffler and dumped at the diff. Sounds so much better than the old leaky system. Also pulled the front bar off and started sussing out how the front mount will fit. Looks like it should fit with aircon staying, ive loosened the reciever dryer and bent it all to the right till the cooler fit with the LH side endtank up against the chassis rail/bumber bracket. Its not central but im not fussed as its matt black anyway. Still have to see if bar will clear. Next up will be cooler piping. How do people usually run it with the abs module there looks like it will be prity tight?

Engine bay as of today  Shot showing the location of egt probe

|

||

| Top | |

||

| ef_falcon_95 |

|

|||

|

I'll be watching how you do the intercooler piping , can you put up a few pics of it when your up to it ?

Cheers

_________________ El XR6 Turbo |

|||

| Top | |

|||

| Who is online |

|---|

Users browsing this forum: No registered users and 52 guests |